Meat stuffing preparation device

A technology for making device and stuffed meat, which is applied in the fields of meat processing, slaughtering, food science, etc. It can solve the problem of not being able to process meat stuffing with different thicknesses, and achieve the effect of proper gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below by means of specific embodiments:

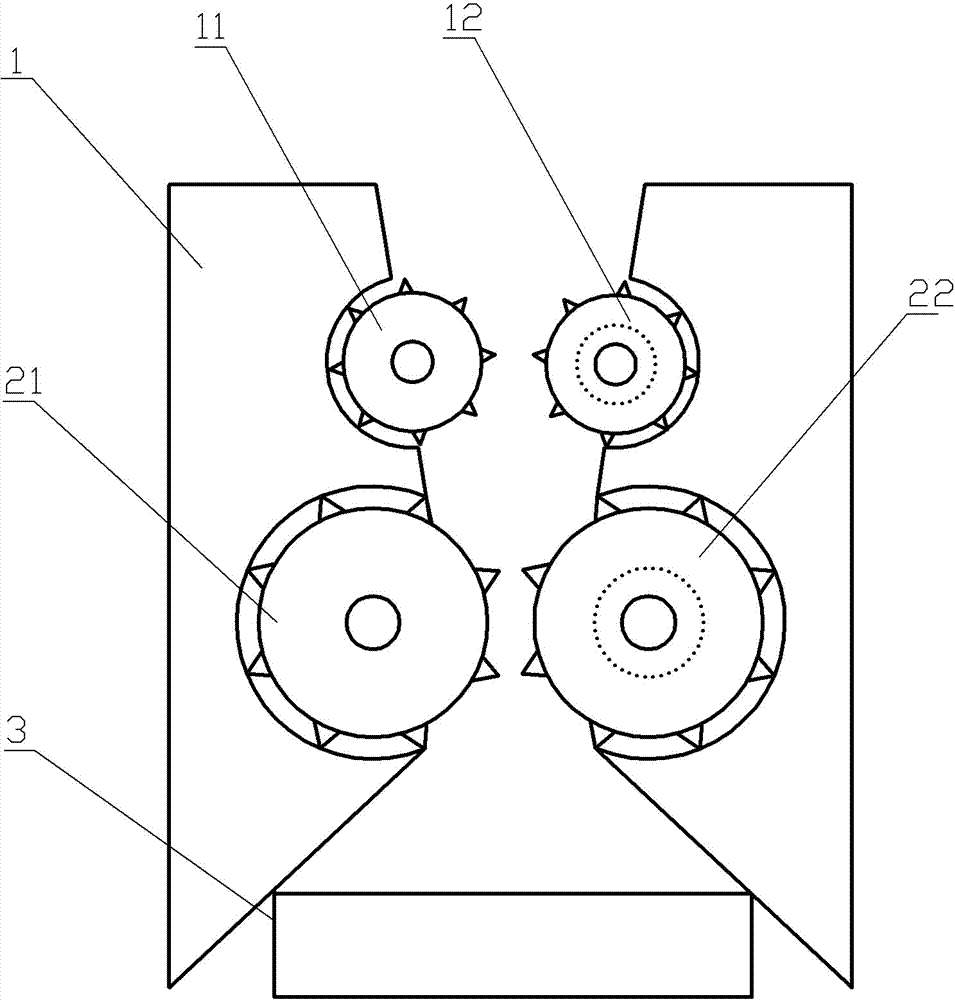

[0013] The reference signs in the accompanying drawings of the specification include: the frame 1 , the first cylindrical roller 11 , the first conical roller 12 , the second cylindrical roller 21 , the second conical roller 22 , and the storage box 3 .

[0014] The embodiment is basically as attached figure 1 Shown: the minced meat making device, including thimble 1, spring 2, sleeve, front positioning block 3, rear positioning block 52 and mandrel 5 arranged in sequence along the axial direction; the front end of the thimble is fixed on the chuck of the lathe, and the rear end of the thimble It passes through the sleeve and is splined with the front positioning block. The center of the front positioning block is provided with a tapered inner hole. The front positioning block is sleeved in the inner hole of the sleeve. A spring is connected between the middle of the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com