Lead-less ball foot surface adhesion type microwave film hybrid integrated circuit and integration method thereof

A hybrid integrated circuit, microwave thin film technology, applied in the direction of circuits, electrical components, electric solid devices, etc. There are many leads, etc., to achieve broad market prospects and application space, reduce the volume, and improve the effect of high-frequency performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

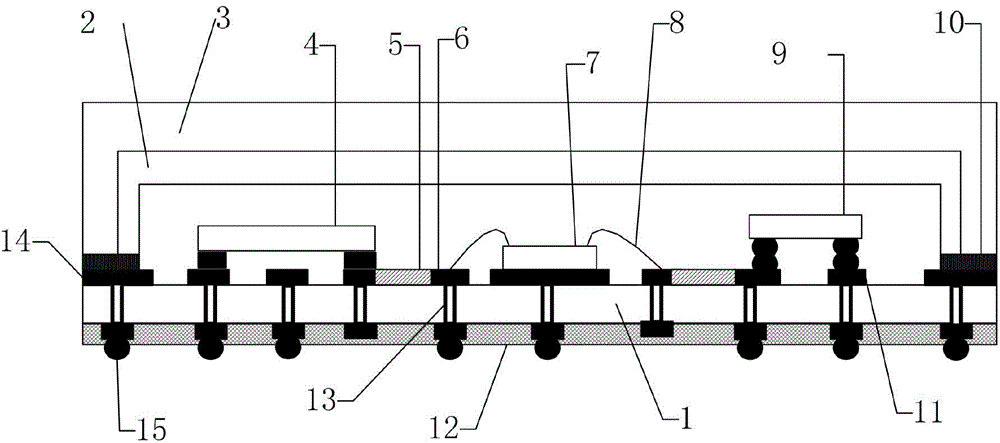

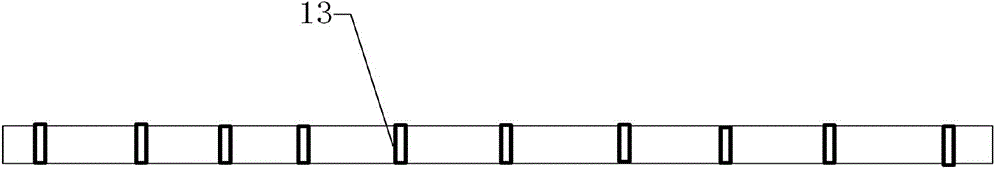

[0032] structured as figure 1 The non-lead ball surface-mounted microwave thin film hybrid integrated circuit is composed of a thin film ceramic substrate 1, a thin film conduction band, a thin film stop band 5, a thin film capacitor, a thin film inductor, a chip component 4, a semiconductor bare chip and a cap; There is a metallized through hole between the front and bottom of the thin film ceramic substrate; the thin film conduction band, the thin film stop band 5, the thin film capacitor and the thin film inductor are integrated on the front of the thin film ceramic substrate 1, and an insulating medium is used on the bottom surface of the thin film ceramic substrate 1 The film 12 is sealed and insulated and protected; the metal ball-type external connection end is made on the bottom surface of the film ceramic substrate 1; Capacitor, thin film inductor, semiconductor bare chip; Semiconductor bare chip comprises front-mounted semiconductor chip 7 and flip-chip semiconductor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com