Batching monitoring and tracing method and system

A recipe, the technology of this system, applied in the direction of instruments, data processing applications, resources, etc., can solve the problems of multiple configurations, equipment redundancy, no traceability, etc., to optimize the batching process, accurate work order generation, and reduce system errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0191] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

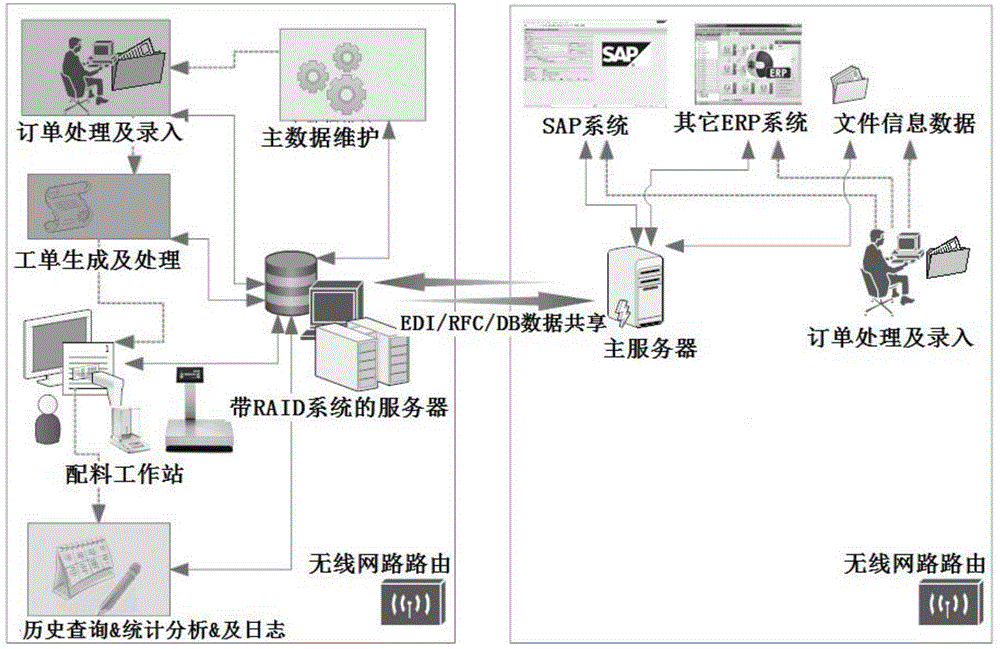

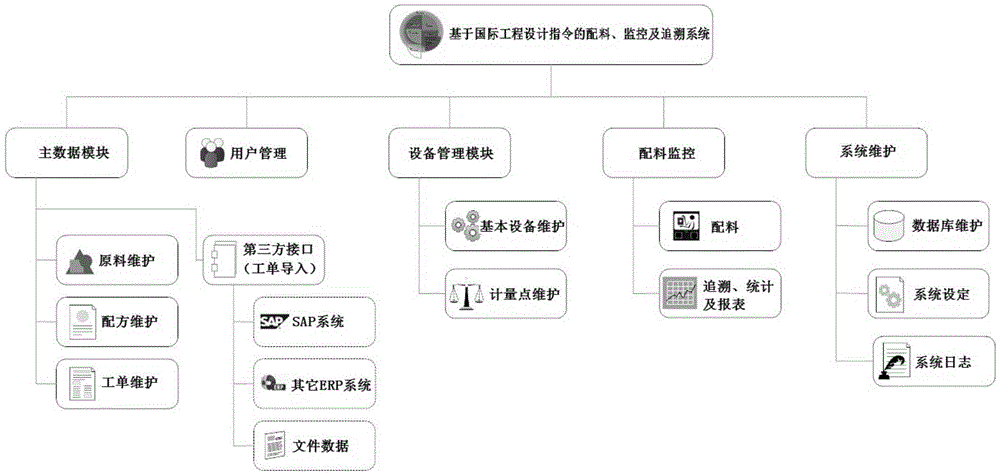

[0192] Such as Figure 1-2 As shown, a traceability method for ingredient monitoring includes the following steps:

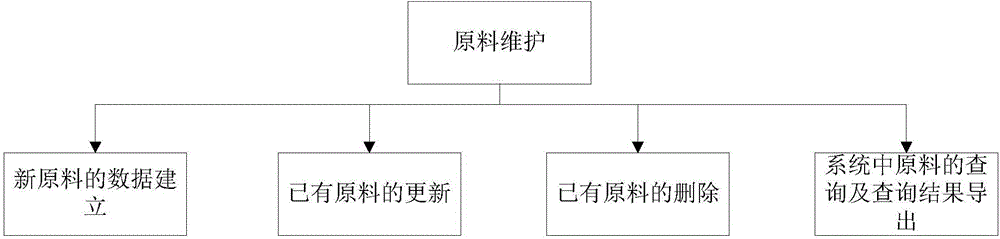

[0193] Step (1): Data maintenance: master data maintenance, user management data maintenance, equipment management data maintenance and system data maintenance;

[0194] Step (2): order processing and entry: establishment and maintenance of sales order information in the system;

[0195] Step (3): Work order generation and processing: According to sales products and quantities, generate work orders based on recipes or obtain work order information from third-party systems;

[0196] Step (4): Batching: Obtain the information of the measurement point through the information of the measurement point or the external barcode, and retrieve the work order / ingredient list from the database; provide the measurement point of the work, the initial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com