Oil fluid surface indicator as well as preparation method of oil fluid surface indicator and application method of oil fluid surface indicator

An indicator, oil level technology, applied in the direction of the level indicator of the level members, can solve the problems of high cost instrument lines, different advanced levels, low instrument accuracy, etc., to reduce production costs, avoid safety risks, measure high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

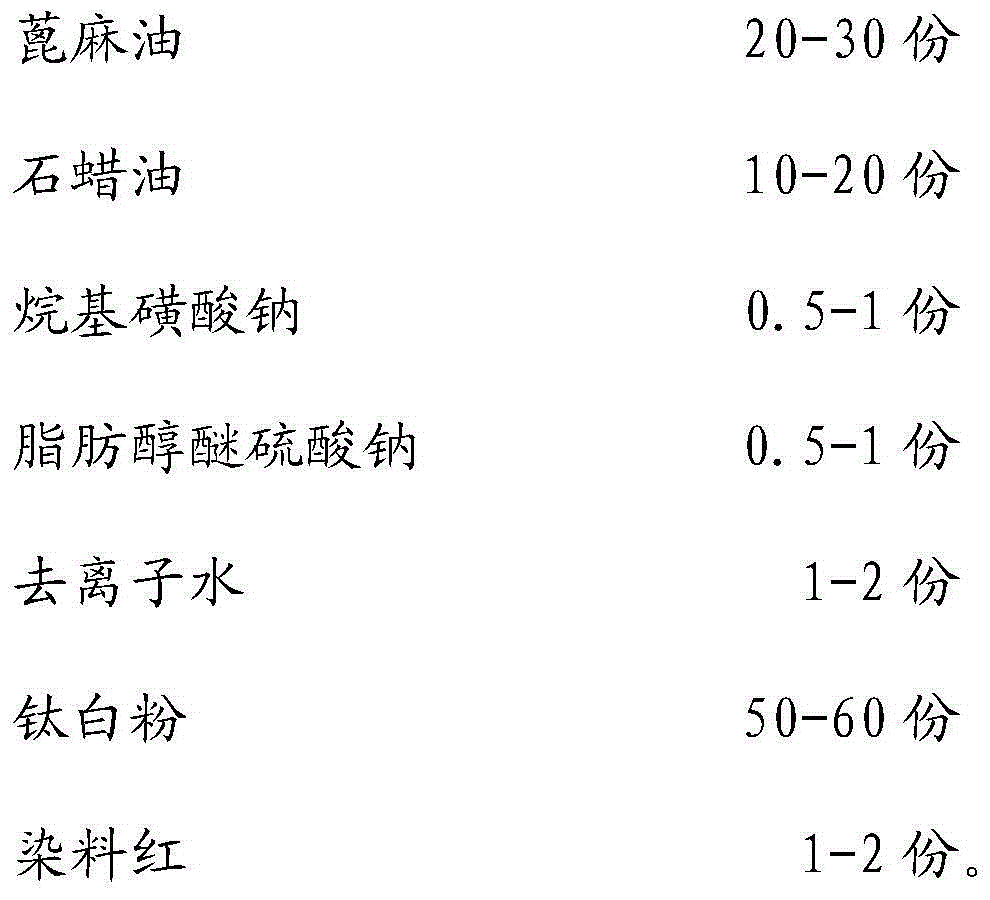

[0028] An oil level indicator is prepared from the following raw materials in parts by weight:

[0029]

[0030] A kind of preparation method of oil level indicator, it is characterized in that, carry out according to the following steps:

[0031] 1) Dissolve sodium alkylsulfonate and sodium fatty alcohol ether sulfate in deionized water at 70°C according to the ratio in the above formula to prepare a surfactant solution for use;

[0032] 2) According to the ratio in the above formula, put castor oil and paraffin oil into the reaction bottle, and stir at 90°C for 15 minutes;

[0033] 3) According to the ratio in the above formula, add the surfactant solution and dye red prepared in step 1) into the reaction bottle that completed step 2), continue to stir for 10 minutes, then add titanium dioxide and stir for 20 minutes, and you are done. Make an oil level indicator.

[0034] A method of using an oil level indicator. When measuring the liquid level of a large oil depot, fi...

Embodiment 2

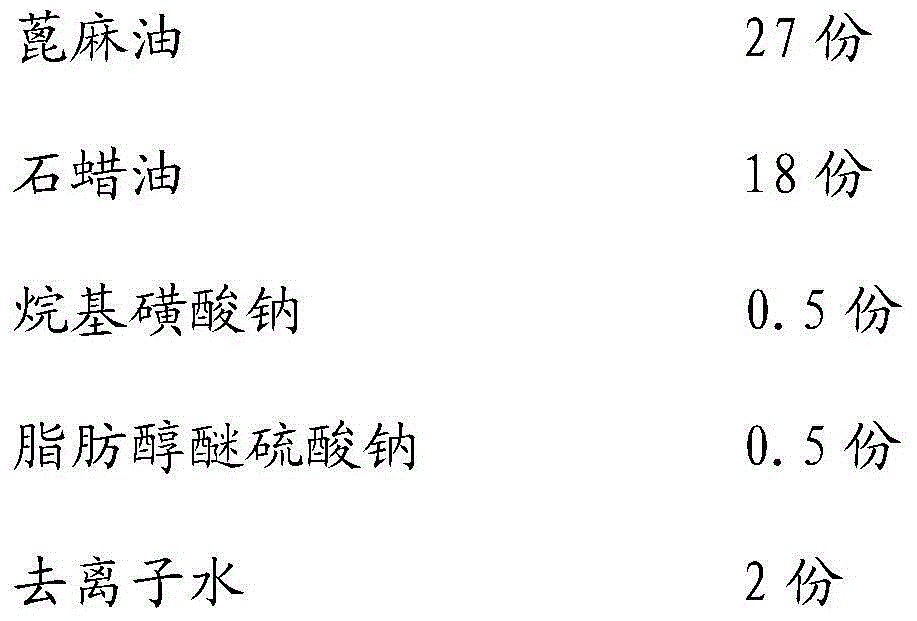

[0036] An oil level indicator is prepared from the following raw materials in parts by weight:

[0037]

[0038] A kind of preparation method of oil level indicator, it is characterized in that, carry out according to the following steps:

[0039] 1) Dissolve sodium alkylsulfonate and sodium fatty alcohol ether sulfate in deionized water at 65°C according to the ratio in the above formula to prepare a surfactant solution for use;

[0040] 2) According to the ratio in the above formula, put castor oil and paraffin oil into the reaction bottle, and stir at 85°C for 14 minutes;

[0041] 3) According to the ratio in the above formula, add the surfactant solution and dye red prepared in step 1) into the reaction bottle that completed step 2), continue to stir for 9 minutes, then add titanium dioxide and stir for 19 minutes, and you are done. Make an oil level indicator.

[0042] The using method of the oil level indicator is the same as that of Example 1.

Embodiment 3

[0044] An oil level indicator is prepared from the following raw materials in parts by weight:

[0045]

[0046] A kind of preparation method of oil level indicator, it is characterized in that, carry out according to the following steps:

[0047] 1) Dissolve sodium alkylsulfonate and sodium fatty alcohol ether sulfate in deionized water at 75°C according to the ratio in the above formula to prepare a surfactant solution for use;

[0048] 2) According to the ratio in the above formula, put castor oil and paraffin oil into the reaction bottle, and stir at 95°C for 16 minutes;

[0049] 3) According to the ratio in the above formula, add the surfactant solution and dye red prepared in step 1) into the reaction bottle that completed step 2), continue to stir for 11 minutes, then add titanium dioxide and stir for 21 minutes, and you are done. Make an oil level indicator.

[0050] The using method of the oil level indicator is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com