Real dam displacement monitoring method under vibration condition

A technology of actual displacement and dynamic displacement, applied in the field of monitoring, can solve problems such as unsatisfactory requirements, lack of performance, and inability to obtain displacement, and achieve the effect of high degree of practicality, easy promotion, and high measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0020] The terms involved in the present invention are explained as follows:

[0021] Dam displacement: The dam is not static. Under the comprehensive influence of various factors, the change of the position of each point on the dam body is the dam displacement.

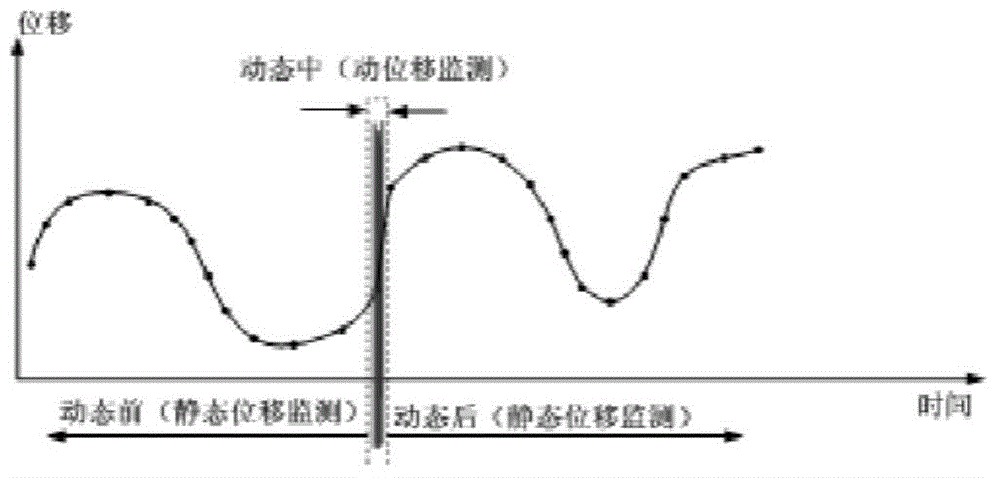

[0022] Static displacement: Under normal circumstances, the displacement of the dam changes very slowly, showing static characteristics. The static displacement changes little in a short period of time, and the human senses can hardly feel it.

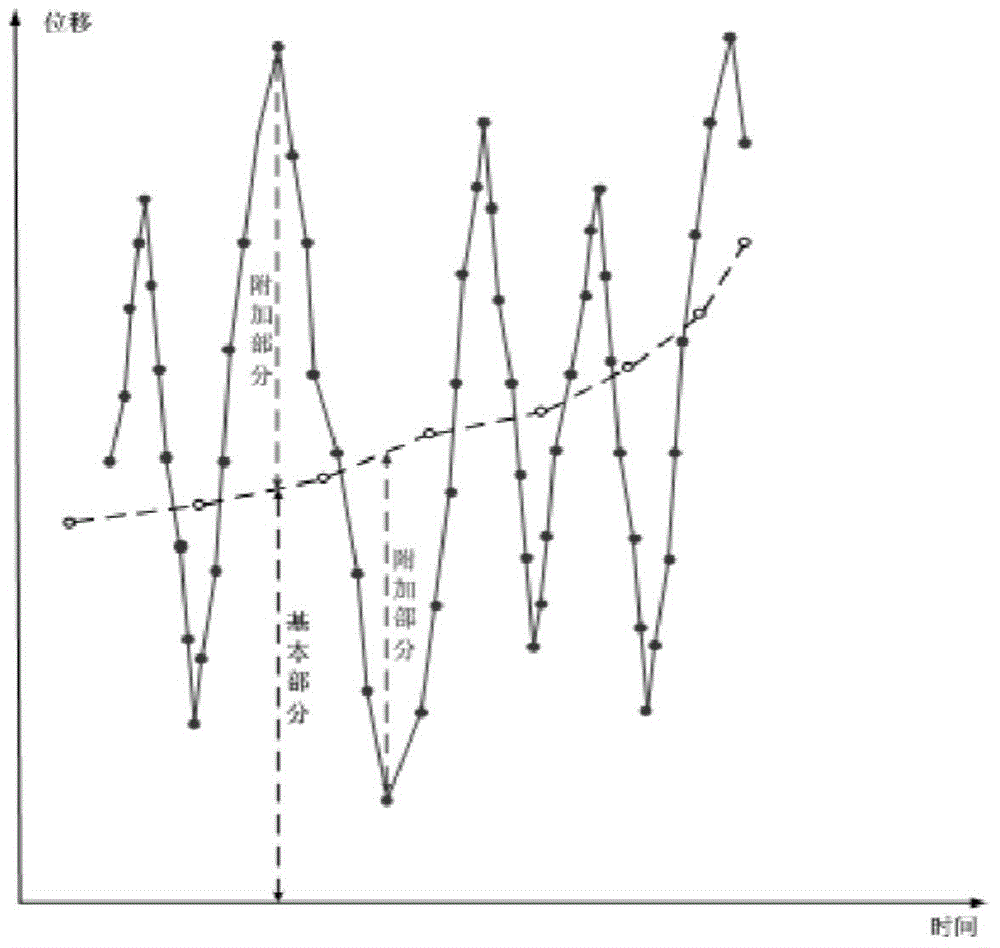

[0023] Dynamic displacement: The reciprocal displacement of the dam relative to the new position due to vibrations near the new position reached after the static displacement. Under the condition of vibration, the displacement of the dam is sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com