Novel rotary drum type coking coal dryer sealing device

A dryer, a new type of technology, applied in the field of sealing, which can solve the problems of packing wear, high surface temperature of the sealing device, and falling off.

Inactive Publication Date: 2015-04-01

CHANGZHOU UNIV

View PDF3 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The packing seal has serious packing wear and often falls off; the deviation of the concentricity of the steam pipe rotary dryer causes the packing to be eccentric, resulting in serious seal leakage; there is no axial compensation device; the linear speed of the packing is high, resulting in high surface temperature of the sealing device. Inconvenient maintenance; short service life of seals, etc.

In order to avoid the contact between the dynamic and static sealing rings during the movement, the labyrinth seal takes into account factors such as thermal expansion and contraction, series motion, bending and radial runout, etc. It cannot be too small, so the biggest disadvantage of the labyrinth seal is that the sealing effect is not ideal, and it can only be used in occasions with low pressure or in combination with other seals

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

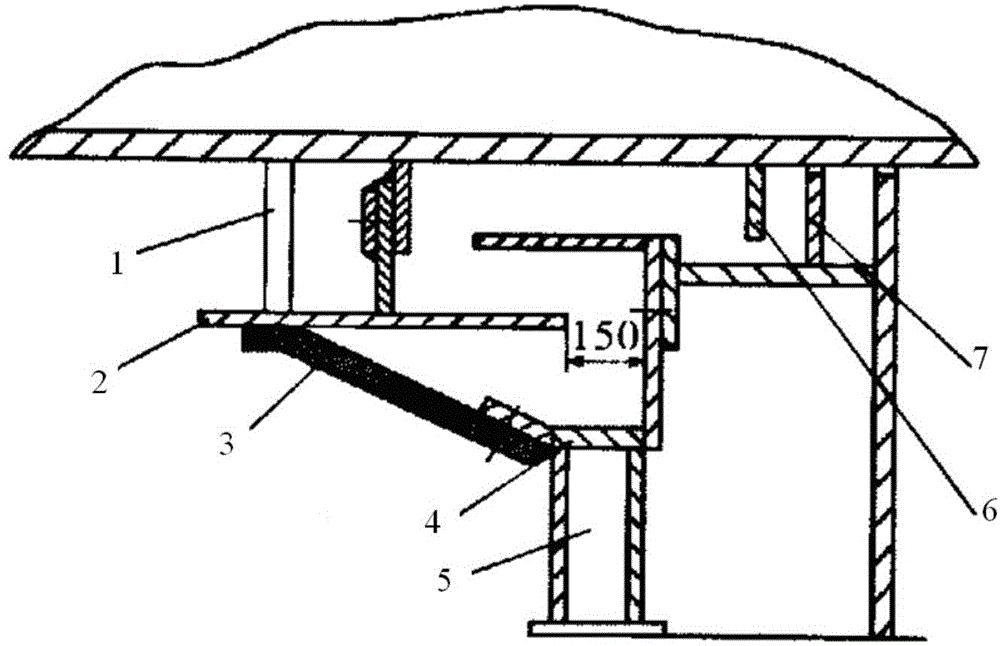

[0008] The coal powder blocked by the sealing device will accumulate in the ash hopper, and when it reaches a certain amount, it will be discharged from the ash hopper. In order to ensure the tight fit between the sealing body and the friction ring, a steel wire rope is hung outside, and the tight fit between the sealing body and the sealing ring is adjusted by adjusting a reasonable weight, so as to meet the sealing requirements.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

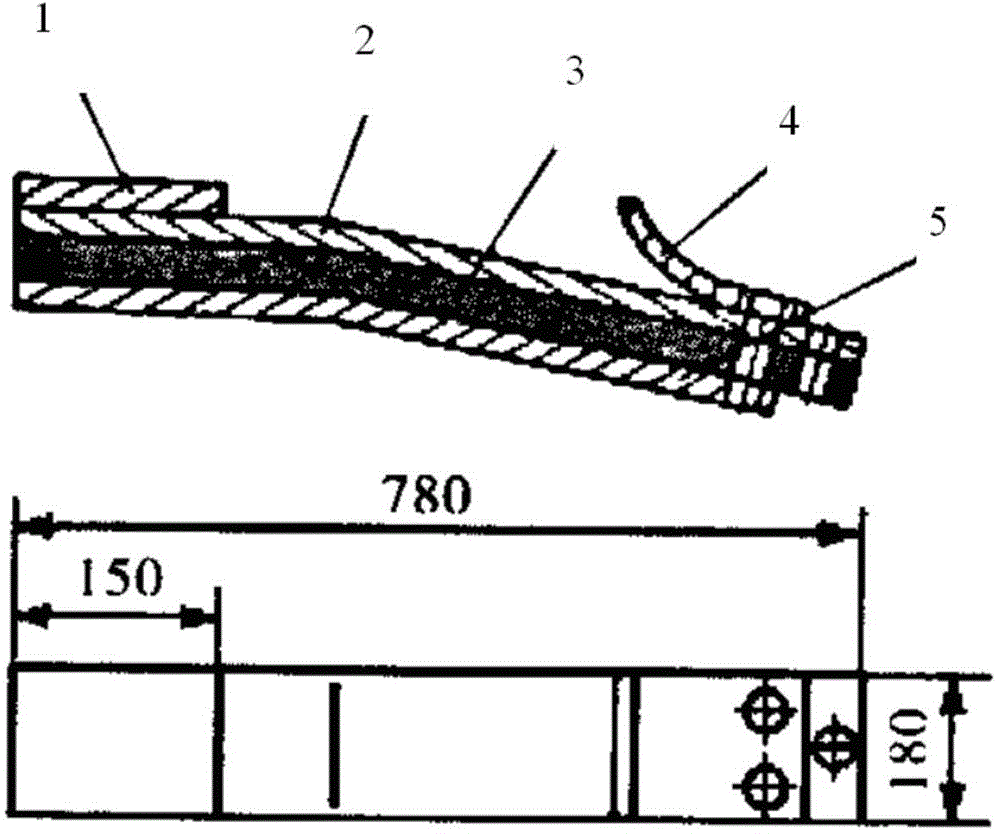

The invention discloses a novel rotary drum type coking coal dryer sealing device. The novel rotary drum type coking coal dryer sealing device comprises an adjusting supporting frame, a friction ring, a sealing body, an ash hopper supporting base, an ash hopper, a small retaining ring and a large retaining ring. The small retaining ring is welded to a drum body and is a movable seal ring. The large retaining ring is welded to a discharge box structure and is a fixed seal ring. A labyrinth seal is formed between the large retaining ring and the small retaining ring. A second labyrinth seal is formed between the ash hopper and the friction ring. The sealing body serves as the last seal and comprises an abrasion resistant plate, a sealing material, a press plate, a friction plate and a reflective plate.

Description

technical field [0001] The invention relates to sealing, in particular to a novel sealing device for a drum type coking coal dryer. Background technique [0002] In order to ensure that the coke oven is produced under the condition that the coal loaded in Shanghai has a stable water content, the coking coal usually needs to be dried to the selected target value before being loaded into the furnace: control the moisture content to about 6%. And this is achieved by the tumble dryer. The oxygen content in the dryer needs to be strictly controlled. When the internal oxygen content exceeds the standard, it may cause danger such as explosion. This requires a more reasonable sealing structure to prevent air leakage, causing the oxygen content inside the dryer to exceed the standard, and preventing the leakage of coal powder, causing problems such as operating environment pollution. [0003] At present, the commonly used sealing devices of drum type coking coal dryer mainly includ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F16J15/447F16J15/16F26B25/00

CPCF16J15/447F16J15/16F26B25/008

Inventor 苏少航王玉平何云松苗乃明

Owner CHANGZHOU UNIV

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com