High-temperature reservoir chemical flooding airtight polymer preparation device

A chemical flooding, high-temperature oil technology, applied in the production of fluids, wellbore/well components, earthwork drilling, etc., can solve the problem of high dissolved oxygen concentration, and achieve the effect of avoiding thermal oxygen degradation and reducing dissolved oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

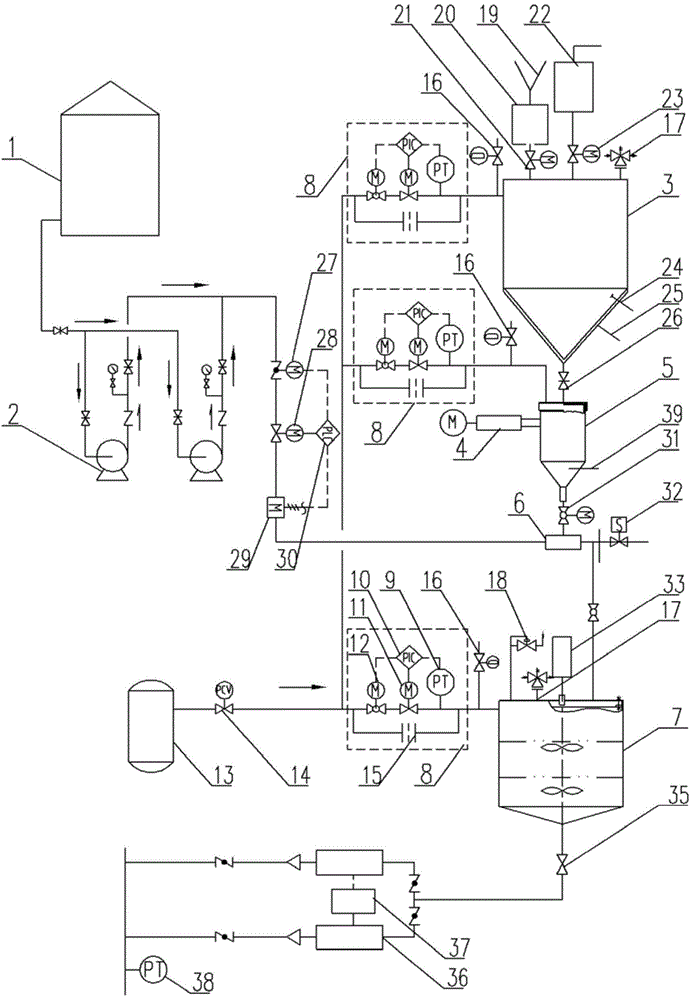

[0022] The high-temperature oil reservoir chemical flooding airtight compounding device of this embodiment, such as figure 1 As shown, it includes a dry powder storage tank 3, a screw feeder 4, a water supply system, a hopper 5, an ejector 6 and a curing tank 7; the dry powder storage tank 3 is a closed polymer dry powder storage tank, and the screw feeder 4 It is a closed frequency conversion screw feeder, the ejector 6 is a plug-in Venturi ejector, the aging tank 7 is a dynamic sealing stirring and dissolving aging tank, and an agitator 33 is installed in the aging tank 7; the receiving hopper 5 is a closed container, The inlet and outlet of the screw feeder 4 are located inside the receiving hopper 5;

[0023] The feeding port of the dry powder storage tank 3 is connected with the inlet of the screw feeder 4 through a pipeline, and the pipeline is provided with a storage tank outlet valve 26; the outlet of the screw feeder 4 is connected with the inner cavity of the receivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com