Electroplating production line conveying trolley

An electroplating production line and wire-passing technology, applied in the direction of electrolysis process and electrolysis components, can solve problems such as insufficient erection of production lines, and achieve the effects of simple structure, stable movement and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

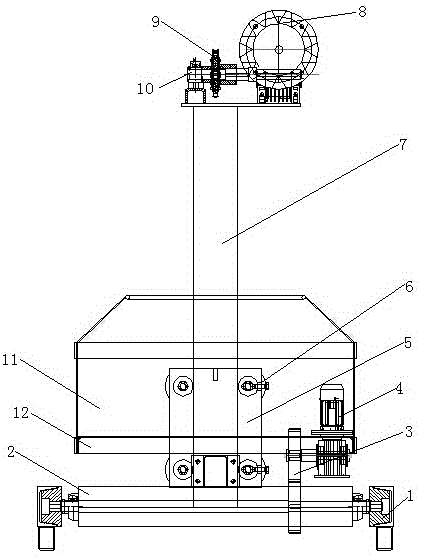

[0013] Such as figure 1 A line-passing trolley of an electroplating production line shown includes a shaping device, a placing device, and a lifting device. Described profile device comprises profile frame 2, profile wheel 1, transmission gear 3 and motor and speed reducer 4, wherein travel wheel 1 is arranged on the two ends of profile frame 2, and profile frame 2 is provided with transmission gear 3 , be arranged on the running frame 2 and be provided with transmission gear 3 and be arranged on the transmission gear 3 on the motor and reducer 4 to cooperate, drive the rotation of running frame 2, thereby drive the movement of line passing trolley.

[0014] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com