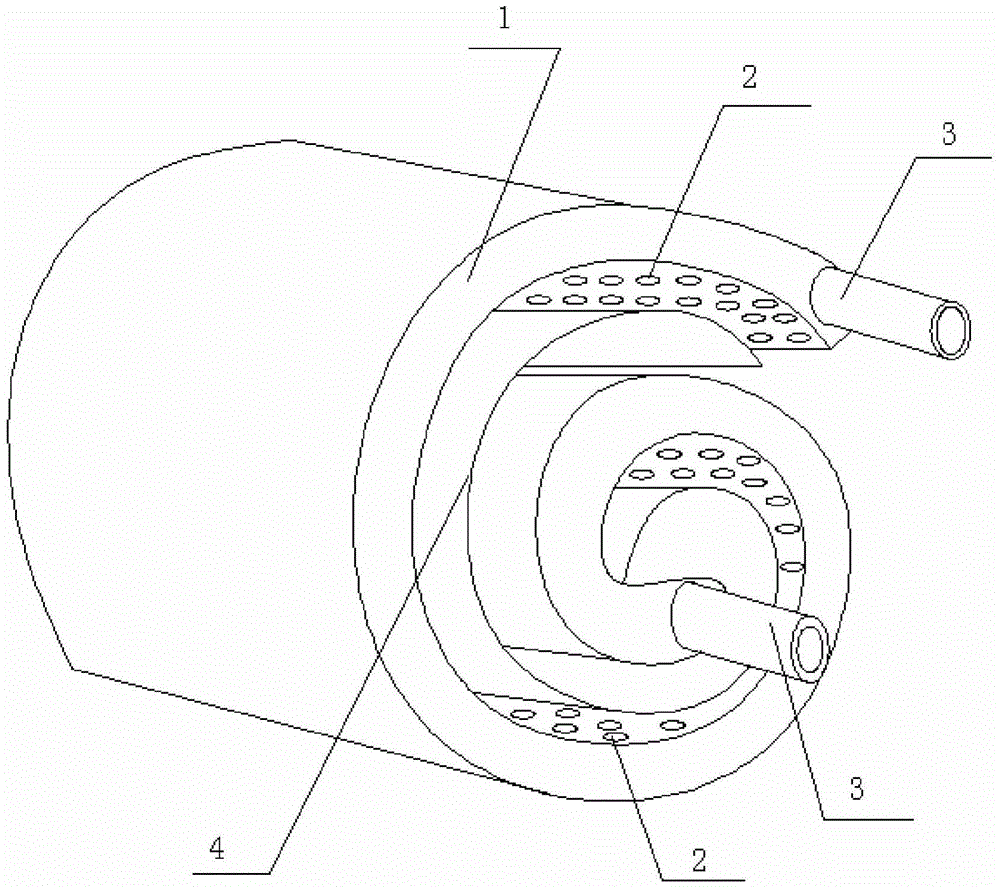

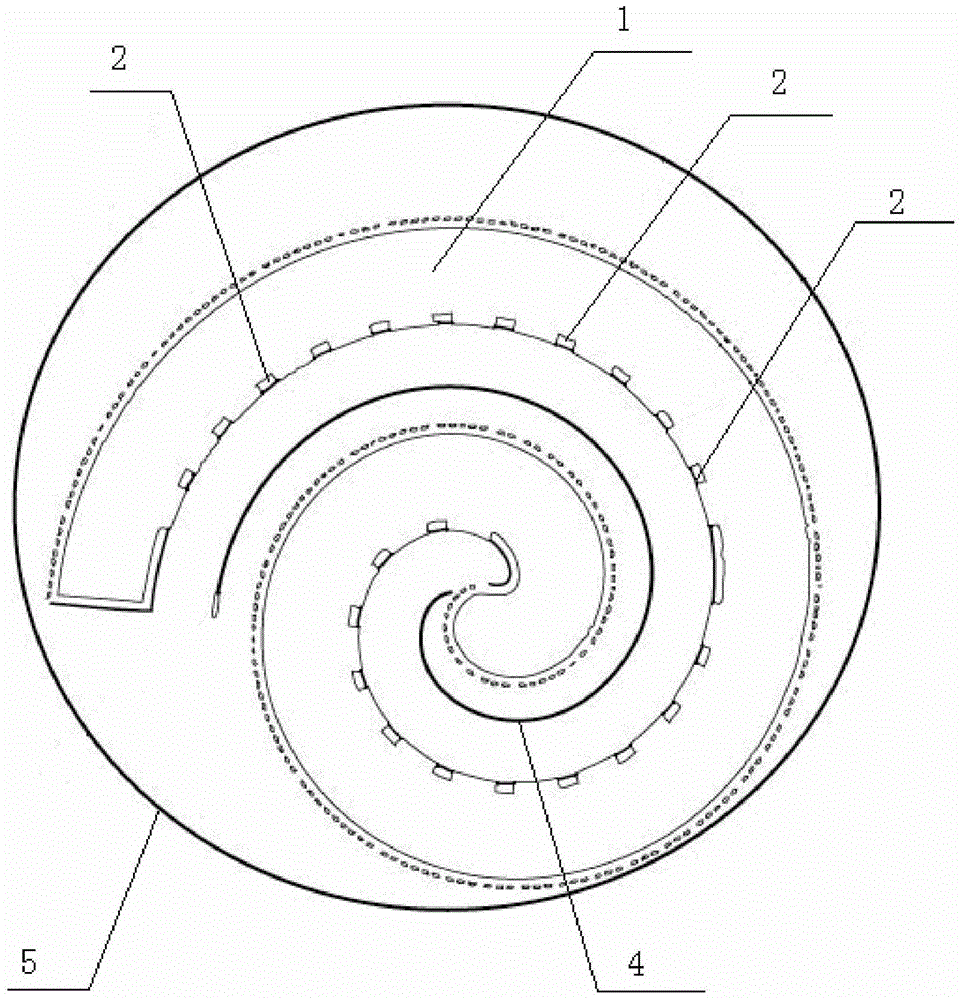

Device for growing graphene in large areas

A graphene, large-area technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of uneven gas distribution, small preparation, low production capacity, etc., to achieve uniform growth and increase output , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] When the internal diameter of quartz tube 5 was 100mm, the thickness of quartz tube 5 tube wall was 2mm; The distance between two adjacent circles of the cavity 1 is 1 mm; the metal base 4 is made of copper foil with a width of 30 cm, and the width of the ventilation cavity 1 is 32 cm. Roll the copper foil with a width of 30cm and a length of 56cm into the ventilation cavity 1. The way of rolling can be to use a soft board with the same thickness as the ventilation cavity 1 to lay under the copper foil, wrap the copper foil into a roll, and then The copper foil is introduced into the ventilation cavity 1 . The ventilation cavity 1 wrapped with copper foil is placed in the constant temperature area of the quartz tube 5, and then the graphene film is deposited by chemical vapor phase.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com