Water capsule for cigarettes using compound salts as wall material and preparation method thereof

A compound salt and water capsule technology, which is applied in the fields of tobacco, application, and tobacco treatment, can solve the problems of high damage rate of water-encapsulated soft capsules and poor uniformity of capsule wall thickness, so as to reduce smoke hazards, soften smoke, reduce stimulating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

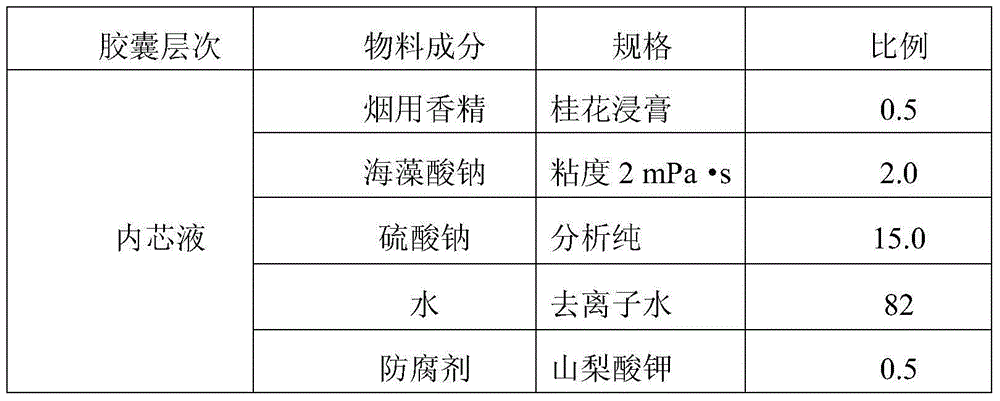

[0022] The water-for-smoking capsule with the compound salt as the wall material, the preparation method thereof comprises the following steps:

[0023] (1) Prepare inner core liquid: prepare 700ml of inner core liquid material according to the ratio described in Table 1 and place it in a 1000ml container with a heating interlayer, heat and stir to mix, dissolve, and leave standstill to obtain inner core liquid;

[0024] (2) prepare the capsule with compound salt inner wall: the inner core liquid of gained in step (1) is dripped in the container that 2000ml 10% calcium chloride is housed and reacted 15min with dropping pill machine, generates compound salt inner wall, promptly has Capsules with compound salt inner wall;

[0025] (3) Preparation of water capsules with compound salt as the wall material: put beeswax and paraffin in the reaction tank according to the ratio in Table 1 and mix evenly to obtain the outer wall material, and place the capsule with the compound salt in...

Embodiment 2

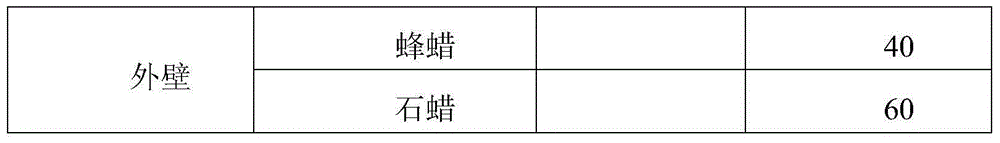

[0031] The water-for-smoking capsule with the compound salt as the wall material, the preparation method thereof comprises the following steps:

[0032] (1) Prepare inner core liquid: prepare 700ml of inner core liquid material according to the ratio described in Table 2, place in a 1000ml container with a heating interlayer, heat and stir to mix, dissolve, and leave standstill to obtain inner core liquid;

[0033] (2) prepare the capsule with compound salt inner wall: the inner core liquid of gained in step (1) is dripped in the container that 2000ml 10% barium chloride is housed and reacted 10min with dropping pill machine, generates compound salt inner wall, promptly has Capsules with compound salt inner wall;

[0034] (3) Preparation of water-to-cigarette capsules with compound salt as the wall material: put beeswax and paraffin in the reaction tank according to the ratio in Table 2 and mix evenly to obtain the outer wall material, and place the capsule with the compound s...

Embodiment 3

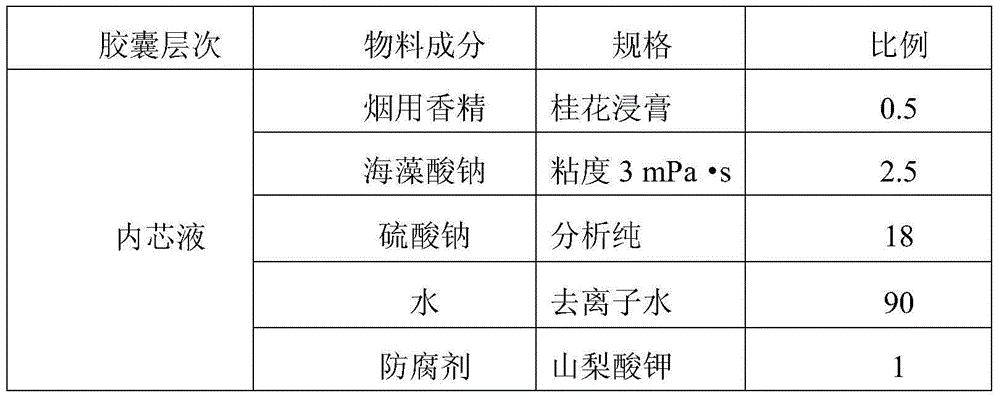

[0040] The water-for-smoking capsule with the compound salt as the wall material, the preparation method thereof comprises the following steps:

[0041](1) Prepare inner core liquid: prepare 700ml of inner core liquid material according to the ratio described in Table 3, place in a 1000ml container with a heating interlayer, heat and stir to mix, dissolve, and leave standstill to obtain inner core liquid;

[0042] (2) preparation has the capsule of compound salt inner wall: the inner core liquid of gained in the step (1) is dripped in the container that 2000ml 5% calcium chloride is housed and reacted 15min with dropping pill machine, generates compound salt inner wall, promptly has Capsules with compound salt inner wall;

[0043] (3) Preparation of water capsules with compound salt as the wall material: put beeswax, paraffin wax and carnauba wax in the reaction tank according to the ratio described in Table 3 and mix evenly to obtain the outer wall material, and the compound ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crushing strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Outer wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com