Nanometer copper/graphene composite material and preparation method and application thereof

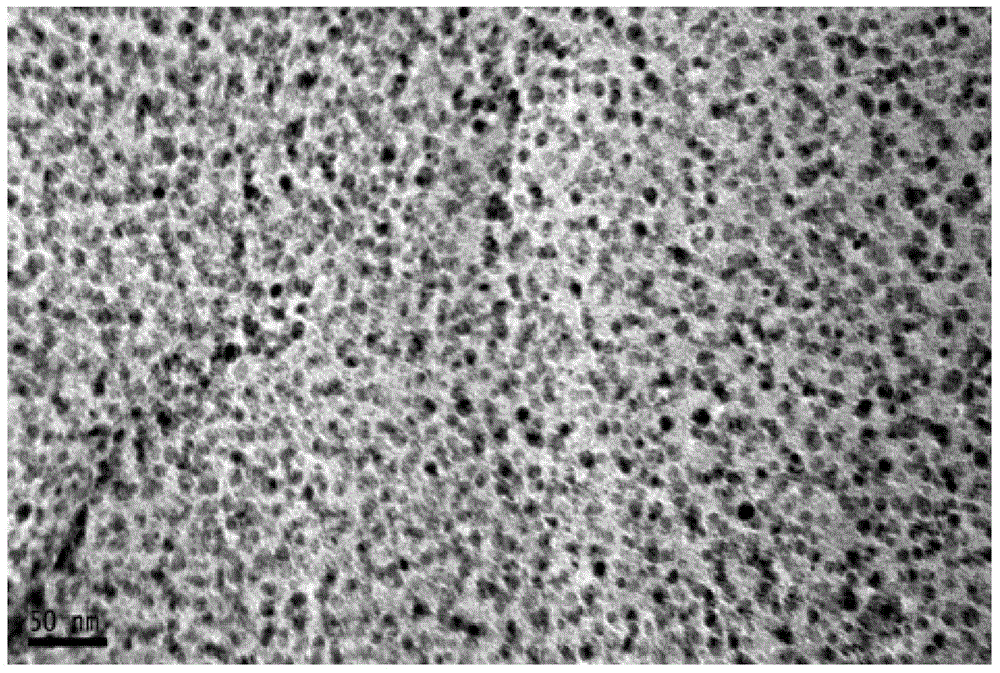

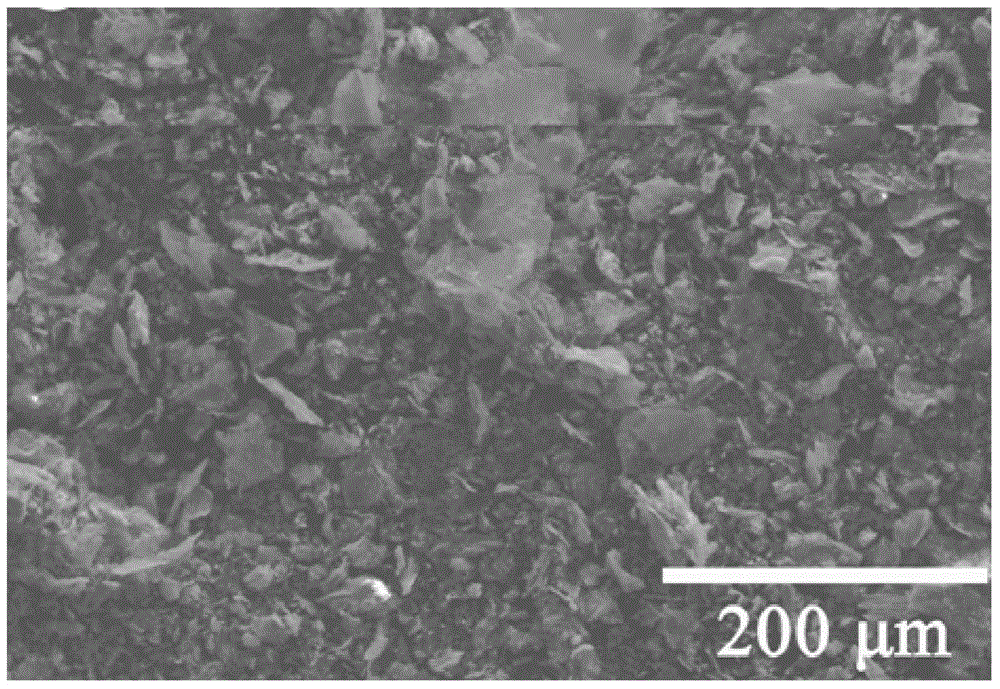

A technology of nano-composite materials and composite materials, which is applied in the field of nano-copper/graphene composite materials and its preparation, which can solve the problems of difficult load control, poor dispersion performance, and small nanoparticles, and achieve short process time and excellent lubricating performance , the effect of small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A kind of nano copper / graphene composite material, its preparation method is as follows:

[0043] (1) At 30°C, add 33mg of copper chloride dihydrate, 5mg of sodium dodecyl sulfate (SDS), and 6mg of sodium citrate into 50ml of absolute ethanol, and stir ultrasonically for 30min to form a uniform solution; then add 100mg of Graphene, ultrasonically dispersed for 1 hour, to obtain a uniformly dispersed mixed solution;

[0044](2) Add 120mg of dimethylaminoborane (DMAB) to the above mixture, stir gently for 1min, then quickly transfer to a 100ml stainless steel reaction kettle, pump in CO 2 Gas, pressurized to 12MPa, heated to 80°C to make CO 2 reaching a supercritical state;

[0045] (3) Stir and react the mixed solution in the reaction kettle in step (2) for 1 hour, then cool to room temperature, release the pressure and exhaust, centrifuge, wash the product with ethanol and deionized water, and dry it in vacuum at 45°C to obtain The nano copper / graphene composite mate...

Embodiment 2

[0047] A kind of nano copper / graphene composite material, its preparation method is as follows:

[0048] (1) At 30°C, add 100mg of copper chloride dihydrate, 5mg of sodium dodecyl sulfate (SDS), and 6mg of sodium citrate into 50ml of absolute ethanol, and stir ultrasonically for 30 minutes to form a uniform solution; then add 100mg of oxidized Graphene, ultrasonically dispersed for 1.5 hours to obtain a uniformly dispersed mixed solution;

[0049] (2) Add 120mg of dimethylaminoborane (DMAB) to the above mixture, stir gently for 1min, then quickly transfer to a 100ml stainless steel reaction kettle, pump in CO 2 Gas, pressurized to 12MPa, heated to 80°C to make CO 2 reaching a supercritical state;

[0050] (3) Stir and react the mixed solution in the reaction kettle in step (2) for 1 hour, then cool to room temperature, release the pressure and exhaust, centrifuge, wash the product with ethanol and deionized water, and dry it in vacuum at 45°C to obtain The nano copper / graph...

Embodiment 3

[0052] A kind of nano copper / graphene composite material, its preparation method is as follows:

[0053] (1) At 30°C, add 300mg of copper chloride dihydrate, 5mg of sodium dodecyl sulfate (SDS), and 6mg of sodium citrate into 50ml of absolute ethanol, and stir ultrasonically for 30min to form a uniform solution; then add 100mg of Graphene, ultrasonically dispersed for 2 hours, to obtain a uniformly dispersed mixed solution;

[0054] (2) Add 120mg of dimethylaminoborane (DMAB) to the above mixture, stir gently for 1min, then quickly transfer to a 100ml stainless steel reaction kettle, pump in CO 2 Gas, pressurized to 12MPa, heated to 80°C to make CO 2 reaching a supercritical state;

[0055] (3) Stir and react the mixed solution in the reaction kettle in step (2) for 1 hour, then cool to room temperature, release the pressure and exhaust, centrifuge, wash the product with ethanol and deionized water, and dry it in vacuum at 45°C to obtain The nano copper / graphene composite m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com