Compounded type cationic polyacrylamide profile control agent and preparation method thereof

A polyacrylamide, cationic technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as short validity period, increase rock viscosity, improve the performance of profile control agent, and increase the viscosity of rock and rock. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention are described in further detail below:

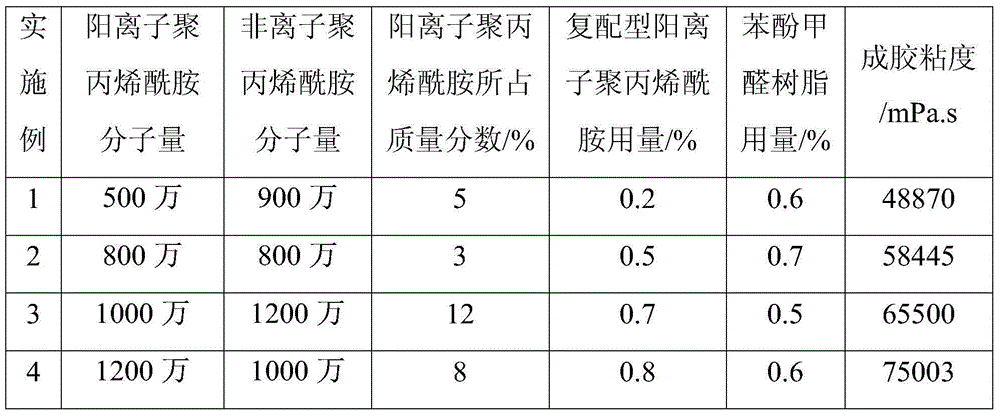

[0024] A compound cationic polyacrylamide profile control agent, by mass fraction, comprising 0.2-0.8% compound cationic polyacrylamide and 0.5-0.7% phenol-formaldehyde resin, and the rest is water; wherein, by mass fraction In total, the composite cationic polyacrylamide includes 3-12% cationic polyacrylamide with a molecular weight of 5-15 million and 88-97% non-ionic polyacrylamide with a molecular weight of 8-12 million.

[0025] Preferably, the composite cationic polyacrylamide includes 8-12% cationic polyacrylamide with a molecular weight of 5-15 million and 88-92% non-ionic polyacrylamide with a molecular weight of 8-12 million in terms of mass fraction.

[0026] Preferably, the composite cationic polyacrylamide includes 8% cationic polyacrylamide with a molecular weight of 5-15 million and 92% non-ionic polyacrylamide with a molecular weight of 8-12 million in terms of mass fraction. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com