A magnetic levitation hydraulic centrifugal device

A centrifugal device and magnetic levitation technology, applied in the mechanical field, can solve the problems of complex control system, strong magnetic field, heavy cooling system, etc., and achieve the effect of simplifying the control system, stable performance, and reducing operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0095] The present invention is described in further detail below in conjunction with accompanying drawing:

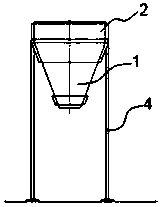

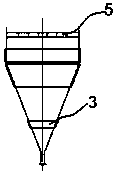

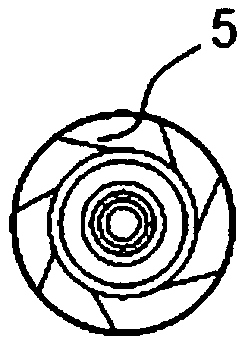

[0096] see figure 1 , 2 3. The maglev hydraulic centrifuge tank is a large cylindrical tank with an inverted conical lower part and a small valve outlet at the bottom. 2-3 or more rotating permanent magnet circles are welded on the outside of the cone, and the magnetic pole direction is N-S from inside to outside, or S-N. In addition, there are 2 to 3 or more fixed permanent magnet coils whose diameter is slightly larger than that of the magnetic levitation hydraulic centrifuge tank, and the magnetic pole direction is just in line with the magnetic pole direction of the rotating permanent magnet coil of the magnetic levitation hydraulic centrifuge tank. on the contrary. Such as figure 2 shown. Like this, when the magnetic levitation hydraulic centrifuge tank is placed on the support frame, because the external magnetic poles of its permanent magnet ring are ident...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com