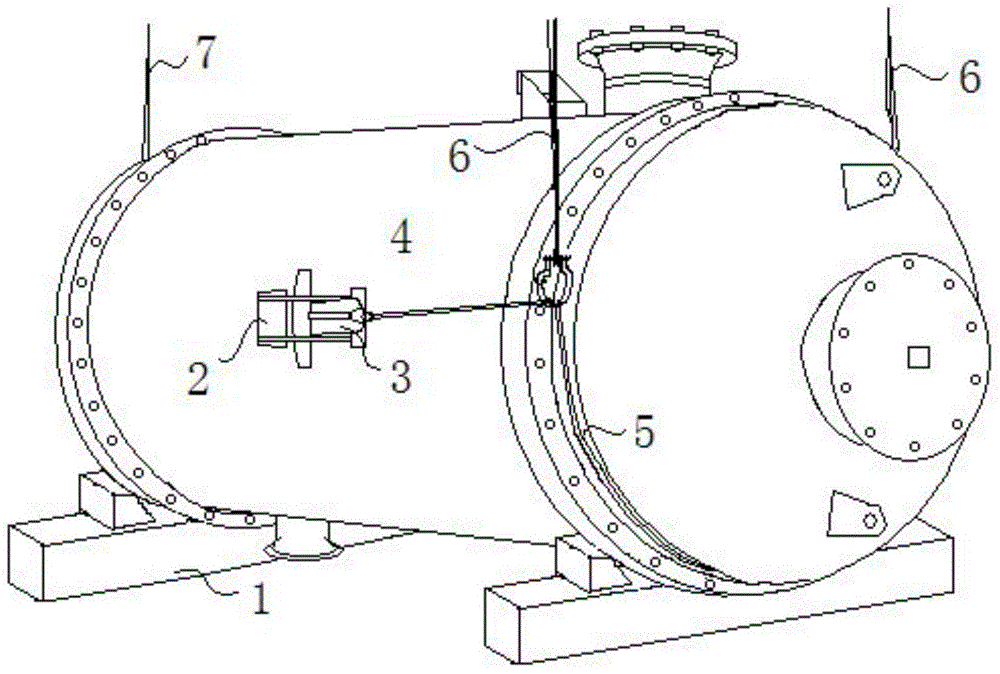

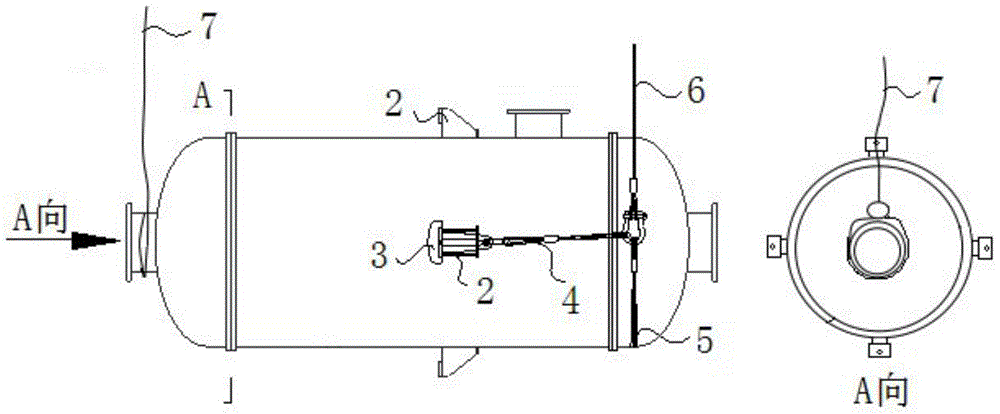

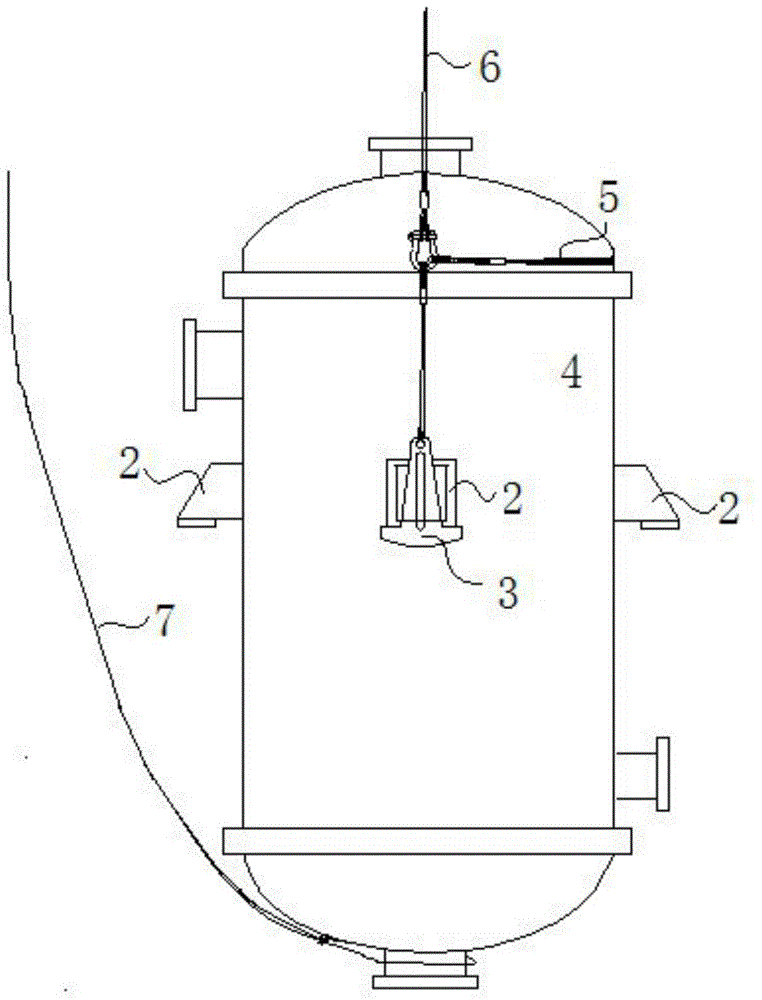

Method for rapidly hoisting suspended type vertical vessel

A hanging and container technology, applied in the direction of load hanging components, transportation and packaging, can solve the problems of easily crushed or scratched equipment, unfavorable equipment perforation in place, large wire rope damage, etc., to save labor costs and The effect of saving labor time, saving procurement and production costs, and saving crane shifts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The Xinjiang Daquan polysilicon project undertaken by a certain unit is equipped with a reboiler before its nine tower equipment in the rectification unit, which belongs to the suspended vertical equipment in the present invention. There are 12 such equipment in the project (equipment weight 17t-36t) needs hoisting. However, the previous method of installing a hanging cover on the top of the equipment is not suitable for this project, because this batch of similar equipment has two top heads without nozzle flanges, and the flanges are on the side of the head. The blue blind plate is sealed, filled with nitrogen for protection, and the pressure shall not be released before the pipeline is installed. The hoisting method of wire rope winding and binding is even more undesirable, extremely unsafe, and the labor intensity is high, and the purchase amount of steel wire rope is large.

[0040] Utilize a kind of method of fast hoisting suspension vertical container of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com