Passenger elevator with novel counterweight fillers

A technology for heavy blocks and elevators, which is applied to elevators in buildings, lifting equipment in mines, elevators, etc., can solve the problems of heavy weight and inconvenience, avoid collision noise, overcome displacement, and satisfy The effect of load requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

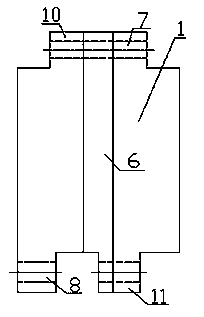

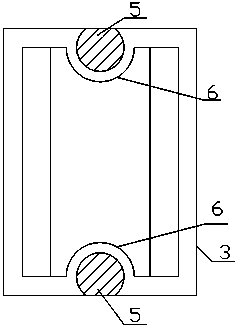

[0013] Example 1. A passenger elevator with a new type of counterweight, the structure of the elevator counterweight is as follows figure 1 and 3 As shown, including a main structure 1, the main structure 1 can be made of cast iron, one end of the main structure 1 is provided with a convex structure 10; the other end of the main structure 1 is provided with a concave-convex structure 11; The protruding structure 10 is provided with positioning holes 7 , the concave-convex structure 11 is provided with fixing holes 8 , and the front and rear of the main structure 1 are provided with through grooves 6 .

[0014] In the present invention, the elevator counterweight is matched with the counterweight guide rail 5 on the counterweight fixing frame 3 through the through groove 6, and the elevator counterweight is fixed on the counterweight fixing frame 3 to meet the load requirements of the elevator. The weight block is relatively small in size, which is very convenient for product...

Embodiment 2

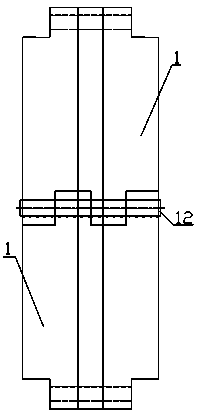

[0015] Example 2. A passenger elevator with a new type of counterweight, the structure of the elevator counterweight is as follows figure 1 , figure 2 and 3 As shown, it includes a main structure 1, the main structure 1 is made of cement, one end of the main structure 1 is provided with a convex structure 10; the other end of the main structure 1 is provided with a concave-convex structure 11; The lifting structure 10 is provided with a positioning hole 7 , the concave-convex structure 11 is provided with a fixing hole 8 , and the front and rear of the main structure 1 are provided with a through groove 6 . A grid-like structure is arranged inside the main structure 1, which can increase the strength of the counterweight. The outside of the elevator counterweight is wrapped by a protective shell, and the protective shell can be made of iron.

[0016] The elevator counterweights of the present invention, when in use, are fixed by the connecting shaft 12 after the concave-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com