Automatic cotton laboratory sample compression forming device

A compression molding and laboratory technology, applied in packaging, presses, manufacturing tools, etc., can solve problems such as inconvenient stacking and stacking, uneven sample bags, and compaction of cotton plugs that are difficult to fluff, so as to prevent fire risks , The overall structure is simple, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

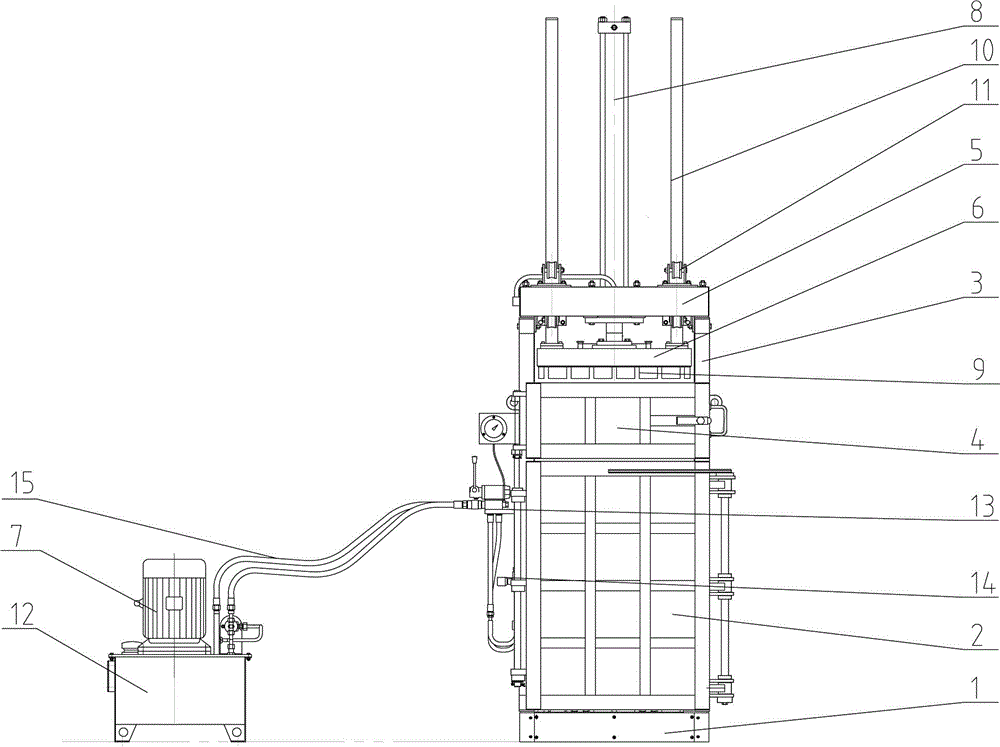

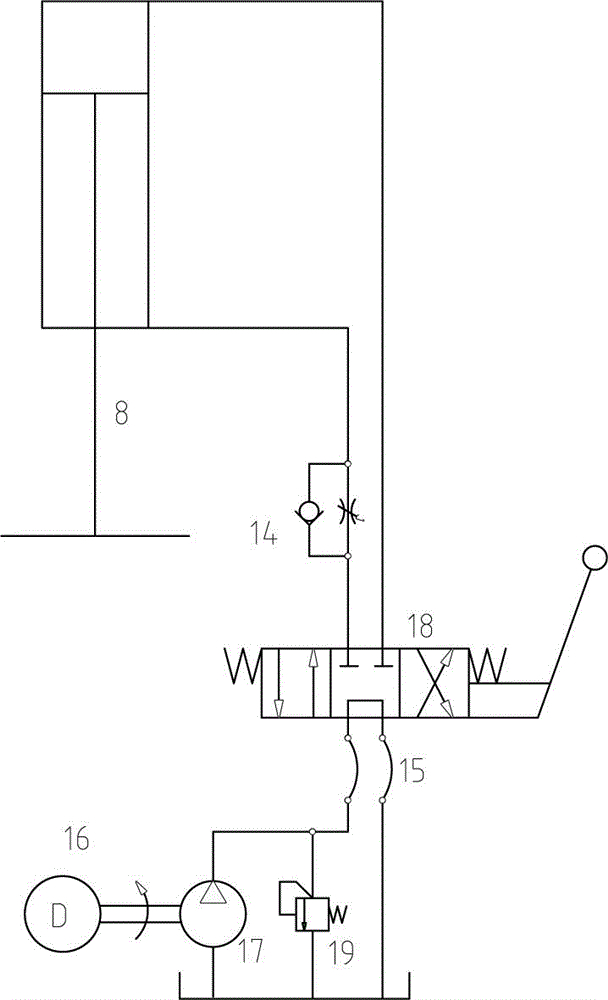

[0012] See attached figure 1 , the present embodiment comprises a base 1, a left and right box panel 3 arranged on the top of the base 1, a lower box door 2 and an upper box door 4 which can be opened front and back on the left box panel and the right box panel 3, and a box door 4 arranged on the left box panel and the right box panel 3. , the crossbeam 5 on the top of the right case plate 3 and the oil cylinder 8 and guide rod 10 that are located on the crossbeam 5 and the guide wheel 11 that is set with the guide rod 10, the bottom of the oil cylinder 8 is provided with a main pressure device 6, and the main pressure The lower part of the device 6 is provided with a plurality of upper pressing heads 9 arranged side by side at a certain distance. The guide rod 10 is connected to the main pressing device 6 after passing through the guide wheel 11 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com