A three-dimensional fluttering flapping wing drive mechanism

A driving mechanism, three-dimensional technology, applied in the directions of helicopters, motor vehicles, aircraft, etc., can solve the problems of low mechanical efficiency flapping aerodynamic efficiency, low mechanical efficiency and aerodynamic efficiency, difficult miniaturization or even miniaturization, etc., to increase transmission reliability. Performance and transmission efficiency, improved mechanical efficiency, easy miniaturization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

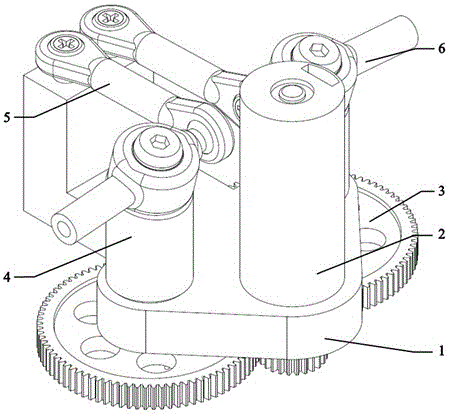

[0031] see Figure 1 ~ Figure 3 , This embodiment provides a flapping wing drive mechanism, including a frame 1, a motor 2, a reduction gear set 3, a linkage guide rod 4, a rocker arm 5, and a ball joint seat connecting rod 6.

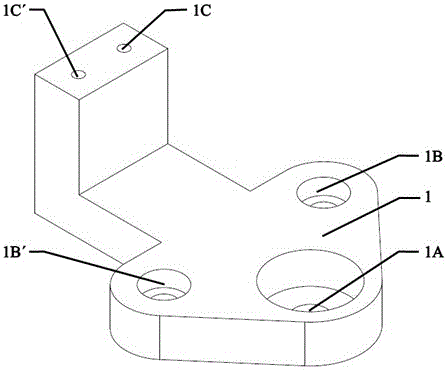

[0032] Rack 1, there is a drive gear shaft hole 1A at the bottom and a pair of driven gear shaft holes parallel to each other, namely the first driven gear shaft hole 1B and the second driven gear shaft hole 1B', and a pair of driven gear shaft holes on the top plane The screw holes are respectively the first screw hole 1C and the second screw hole 1C', which are used to securely connect the ball hinge;

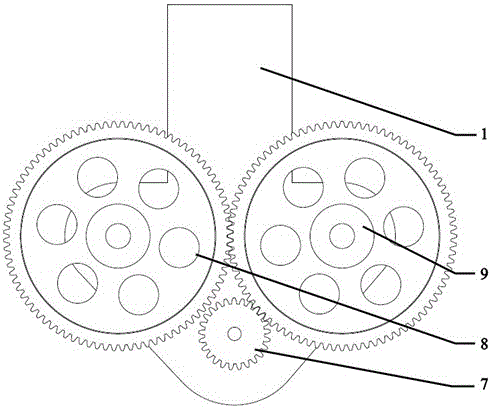

[0033] The motor 2 and the reduction gear group 3 are directly installed on the frame 1. The reduction gear group includes a driving gear 7 and two driven gears, which are respectively a first driven gear 8 and a second driven gear 9, and the first driven gear Gear 8 and the second driven gear 9 are symmetrically distributed on the frame 1, wherein t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com