Quick clamping device for wood door

A clamping device and fast technology, applied in wood processing equipment, special forming/shaping machines, manufacturing tools, etc., can solve problems such as processing efficiency defects, and achieve the effect of fast clamping speed and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below by means of specific embodiments:

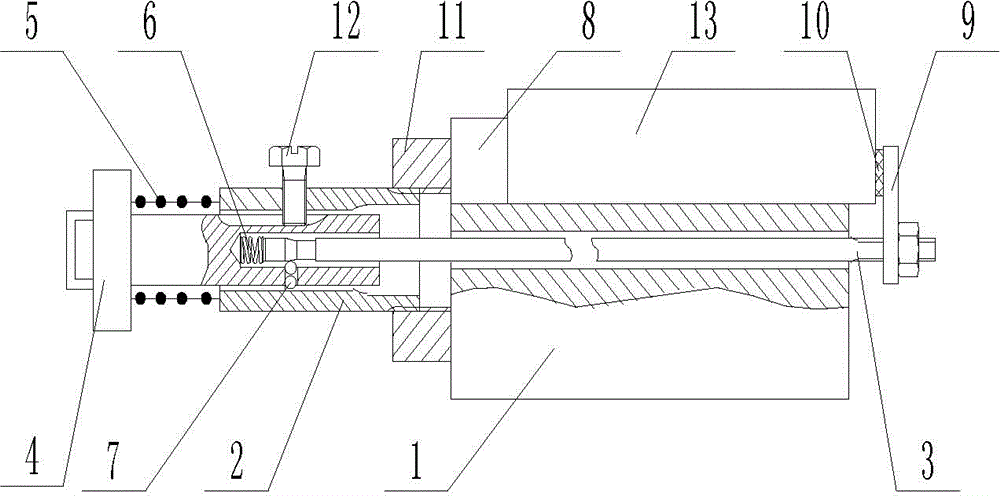

[0013] The reference signs in the drawings of the description include: base 1, sliding sleeve 2, pull rod 3, pull sleeve 4, first spring 5, second spring 6, steel ball 7, fixed baffle 8, movable stop 9, elastic pad 10. Lock nut 11, screw 12, wooden door 13.

[0014] The embodiment is basically as attached figure 1 Shown: wooden door 13 fast clamping devices comprise base 1, sliding sleeve 2, pull bar 3 and pull sleeve 4. The sliding sleeve 2 is threadedly connected with the base 1 , the pulling sleeve 4 is socketed with the sliding sleeve 2 , the pulling sleeve 4 is located in the sliding sleeve 2 , and the pull rod 3 passes through the base 1 . The base 1 is provided with a longitudinal through hole, and the diameter of the through hole is 20 mm larger than the diameter of the pull rod 3 . A lock nut 11 is welded on the left end surface of the base 1, and the axis of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com