Manipulator separating and classifying device

A separation device, manipulator technology, applied in the direction of manipulator, program control manipulator, chuck, etc., can solve the problems of ineffective separation and classification, personnel injury accidents, easy failures, etc., to avoid scratches and safety accidents, and reduce human resources. Cost, the effect of ensuring the quality of castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

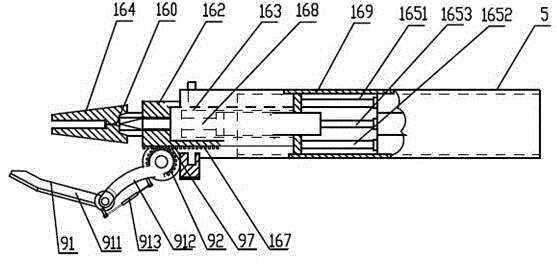

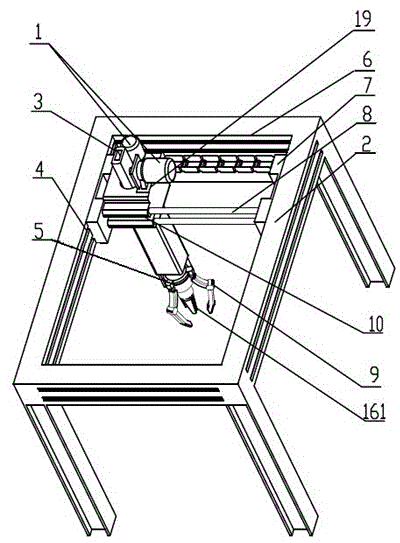

[0026] The invention discloses a device for separating and sorting manipulators, as shown in the attached figure 1 As shown, it includes a mobile seat frame 6, which can be fixed on both sides of the scale machine, and a first mobile actuator 10 is arranged on the mobile seat frame 6, and the first mobile actuator 10 includes guide rails The crossbeam 7 and the mobile guide rail 8 fixed between the guide rail crossbeams 7; The longitudinal movement guide rail 4 moves longitudinally.

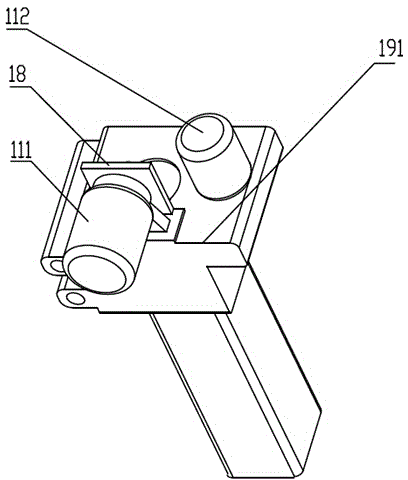

[0027] combined with figure 2 As shown, a main body device 19 is movably clamped on the moving guide rail 8 , and the main body device 19 includes a body 191 that moves laterally on the moving guide rail 8 . A driving motor unit 1 and a limit controller 18 are arranged above the body 191 , and the driving motor unit 1 includes a lifting motor 111 and a moving motor 112 . The bottom of the body 191 is provided with a mechanical arm 5 that can move axially relative to the body 191. The limit co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com