Wind power blade web plate perpendicularity regulating tooling and regulating method

A wind turbine blade, verticality technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of increased operation time, heavy positioning device weight, beam deformation, etc., to ensure positioning accuracy, reduce positioning deviation, and meet the needs of The effect of force requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in conjunction with accompanying drawing and specific embodiment:

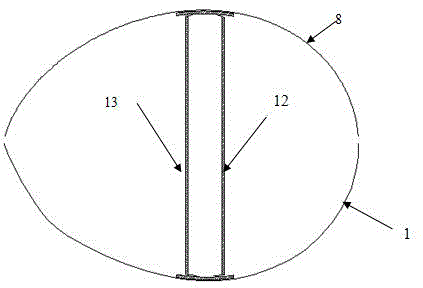

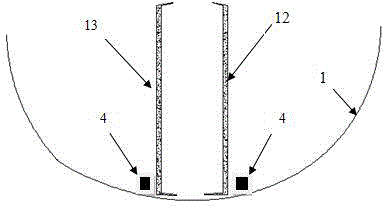

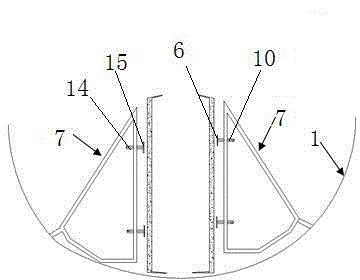

[0026] Such as image 3 shown, combined with figure 1 , figure 2 , a wind power blade web verticality adjustment tool, the adjustment tool has an adjustment frame 7, and the adjustment frame 7 is two groups respectively corresponding to the leading edge web 12 and the trailing edge web 13 of the web, The two groups of adjustment frames are respectively located on the outer sides of the front edge web 12 and the rear edge web 13 of the web; The length direction of the adjustment frame is arranged in a row; the adjustment frame 7 has at least one vertical surface vertical to the horizontal plane; in this embodiment, there is one vertical surface; The edge web 12 and the rear edge web 13 are arranged correspondingly; the adjustment element that can move back and forth is arranged on the described facade; the adjustment element is at least two arranged up and down; in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com