Welding Robot

A technology for welding robots and robot bases, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., to achieve the effects of improving work efficiency, ensuring normal use, and facilitating promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

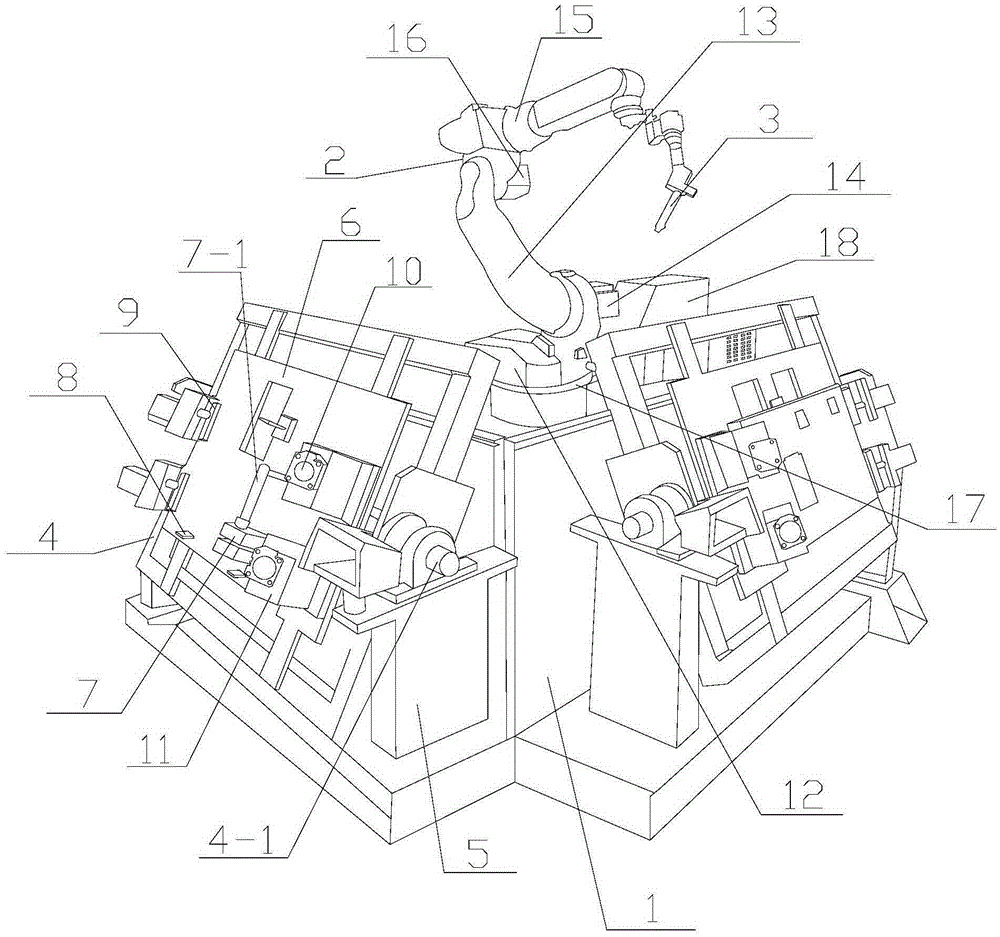

[0012] The present invention will be further described below in conjunction with accompanying drawing:

[0013] With reference to accompanying drawing: this welding robot among the present embodiment comprises a robot base 1, and the top surface of robot base 1 is connected with the manipulator 2 that is used for welding switchgear chassis car, and the bottom surface of manipulator 2 is connected to the bottom surface of robot base 1. On the top surface, the outer end of the manipulator 2 is connected with an argon arc welding torch 3 for welding the switch cabinet chassis. The overturning platform 4 of multi-directional welding, the overturning platform 4 is connected on the robot base 1, and the support 5 for installing the overturning platform 4 is connected between the overturning platform 4 and the robot base 1, and the overturning platform 4 is connected by rotating shaft 4-1. On the support 5, the support 5 is fixedly connected to the robot base 1, and the surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com