One-step molding knife for metal workpiece

A metal workpiece, disposable technology, applied in the direction of metal processing equipment, drilling tool accessories, manufacturing tools, etc., can solve the problems of low efficiency, low efficiency, and failure to meet actual needs, etc., and achieve the effect of convenient and flexible use and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

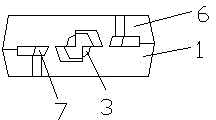

[0020] see figure 1 , figure 2 and image 3 , as can be seen from the figure, the metal workpiece disposable forming knife of the present invention includes a main knife seat 1, and an integrally formed knife handle 2 is provided on the upper surface of the main knife seat 1, and the knife handle 2 is used to connect with the power shaft. A drilling reamer is provided at the center position of the lower surface of the main tool seat 1, and two waste slag grooves 3 drawn through are provided in the vertical direction of the drilling reamer, so that the drilling reamer rotates symmetrically along its own rotation center. The drill reamer is composed of an upper and lower drill reamer body for processing different apertures formed in one piece, wherein the drill reamer body 4 for processing a coarse aperture is located between the main tool holder 1 and the drill reamer bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com