Voltage-reduction structure LED driving circuit, and constant current driver and design method thereof

A technology of LED driving and constant current, applied in the direction of electric lamp circuit layout, instrument, electric light source, etc., can solve the problems of unfavorable circuit miniaturization, large volume of inductance L1, and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

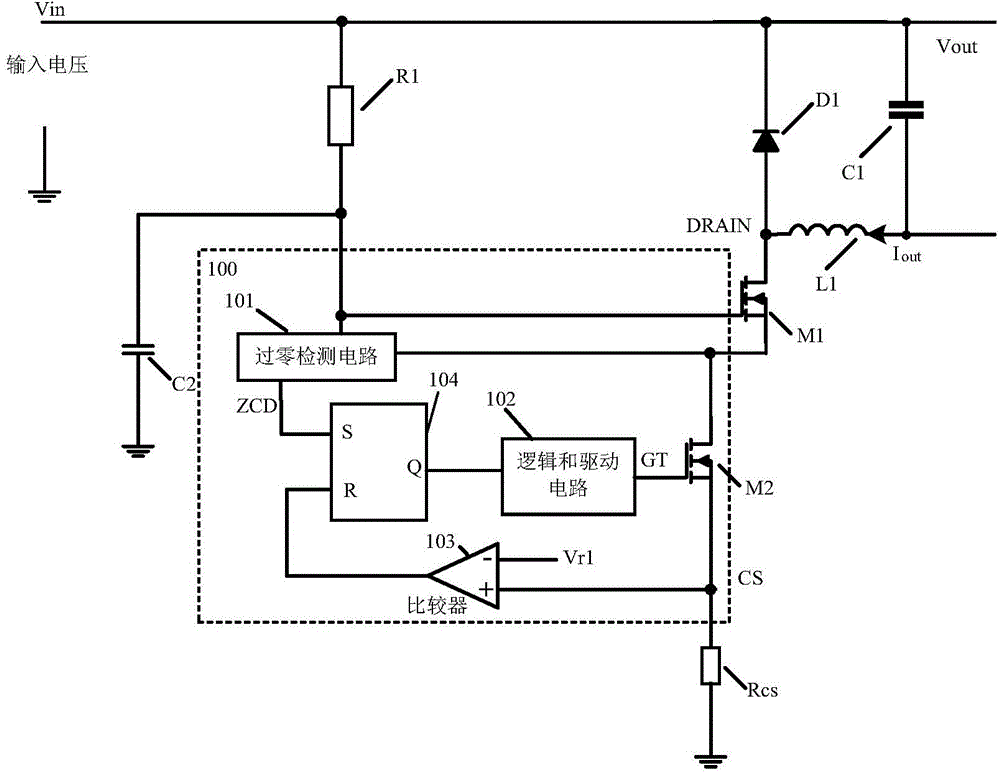

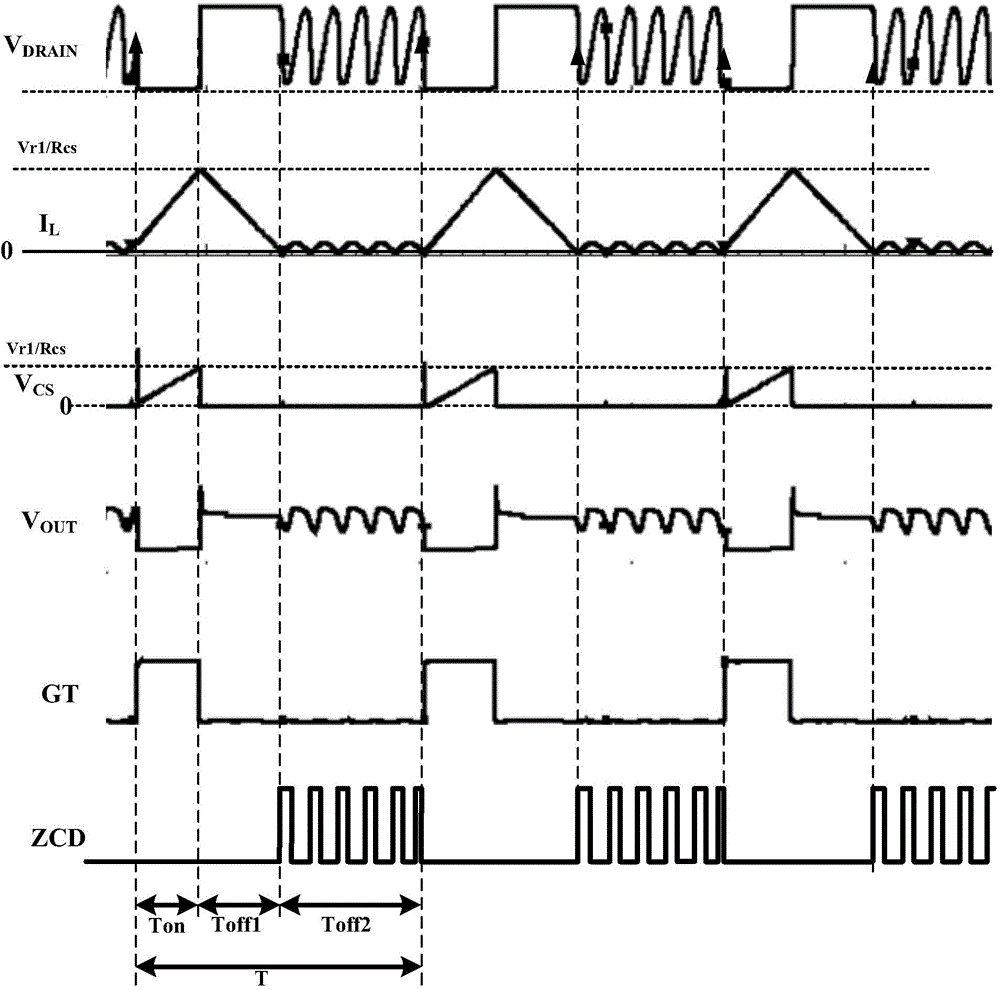

[0116] refer to figure 2 , The step-down structure LED driving circuit of the first embodiment includes: an input resistor R1 , an input capacitor C2 , a freewheeling diode D1 , a load capacitor C1 , an inductor L1 , a sampling resistor Rcs and a constant current driver 200 . Wherein, the constant current driver includes: a power switch, which may include a power tube M1 and a power tube M2; a zero-crossing detection circuit 201; a peak current comparator circuit 203; an opening signal generation circuit 205; a driving circuit 210, the driving circuit 210 RS flip-flop 204 and logic and drive circuit 202 may be included.

[0117] Among them, the first end of the input resistor R1 is connected to the input voltage input terminal Vin; the first end of the input capacitor C2 is connected to the second end of the input resistor R1, and its second end is grounded; the cathode of the freewheeling diode D1 is connected to the input voltage input terminal. Terminal Vin; the first end...

no. 2 example

[0136] refer to Figure 7 , Figure 7 The buck structure LED driver circuit shown in the second embodiment with figure 2 Basically the same, the difference is that the power switch of the second embodiment only includes the power transistor M3, the drain terminal of which is connected to the first terminal of the inductor L1, the gate terminal of which receives the driving signal GT, and the source terminal of which is grounded through the sampling resistor Rcs. The connection structures and working principles of other components in the second embodiment are the same as those in the first embodiment, and will not be repeated here.

[0137] To sum up, the present invention provides a LED drive circuit with a step-down structure and its constant current driver, which uses the peak current of the inductor to control the turn-on time of the power switch, uses the turn-on signal generating circuit to determine the turn-off time of the power switch, and turns on the signal generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com