Ultrasonic wire bonding wire-lost detection device and method

A wire-bonding and wire-detection technology, applied in measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problems of slow detection, waste of manpower, untimely failure, etc., achieve concentrated distribution of characteristic values, and reduce false alarms rate, detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

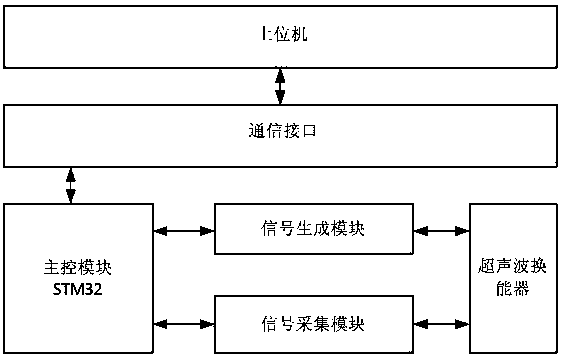

[0025] refer to figure 1 Shown: device of the present invention is mainly by above figure 1 Composed of 6 modules shown in : The detected signal is the impedance signal during the ultrasonic wire bonding process. Therefore, the above hardware structure is required to collect the impedance signal in real time during the working process. The functions completed by each module are as follows:

[0026] 1. Host computer: human-computer interaction interface, the operator can set the bonding parameters and disconnection detection parameters.

[0027] 2. Communication interface: realize the real-time data transmission between the lower computer and the upper computer, and transmit the alarm signal to the upper computer in time when a disconnection fault is detected.

[0028] 3. Main control module: The core chip is STM32, which realizes the decoding of the upper computer, the generation instruction of the driving signal, the processing of the collected signal and the realization o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com