Special annular standard sample for quantitative carbon and sulfur analysis and manufacturing process of special annular standard sample

A circular and standard sample technology, applied in the field of metallurgical analysis, can solve the problems of slow processing speed, high cost, easy pollution, etc., and achieve the effect of improving detection speed, short processing process and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples, and the examples should not be regarded as limiting the protection scope of the present invention.

[0029] The manufacturing method of the special standard sample for annular quantitative carbon and sulfur analysis adopts the following steps:

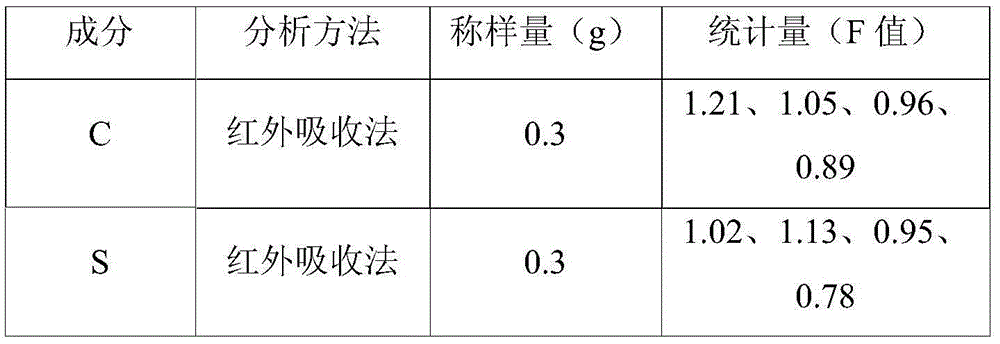

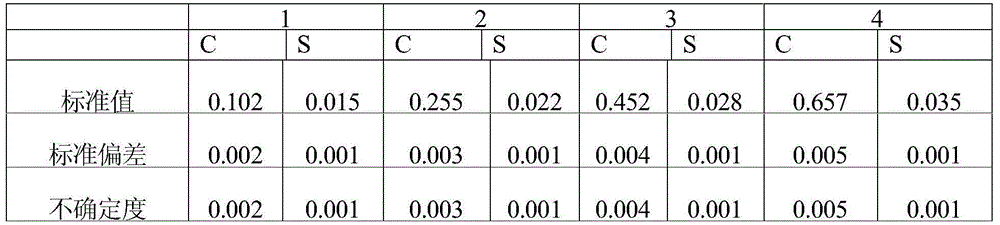

[0030] a. Composition design C 0.10%~0.75%; S 0.010%~0.035%;

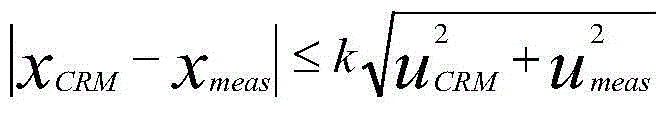

[0031] b. Preparation method When preparing, the uniformity of the composition should be ensured firstly, and the second is to ensure that the content of C and S elements meets the design requirements, and the inclusions in the alloy steel should be reduced as much as possible. For this reason, when selecting raw materials (wire rods), attention should be paid to raw materials that are compatible with the composition. After removing sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com