Geometric parameter visual measurement method for large composite board

A composite plate and visual measurement technology, applied in the field of visual measurement, can solve the problems of cumbersome operation, expensive, easy to scratch the surface of the workpiece, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions.

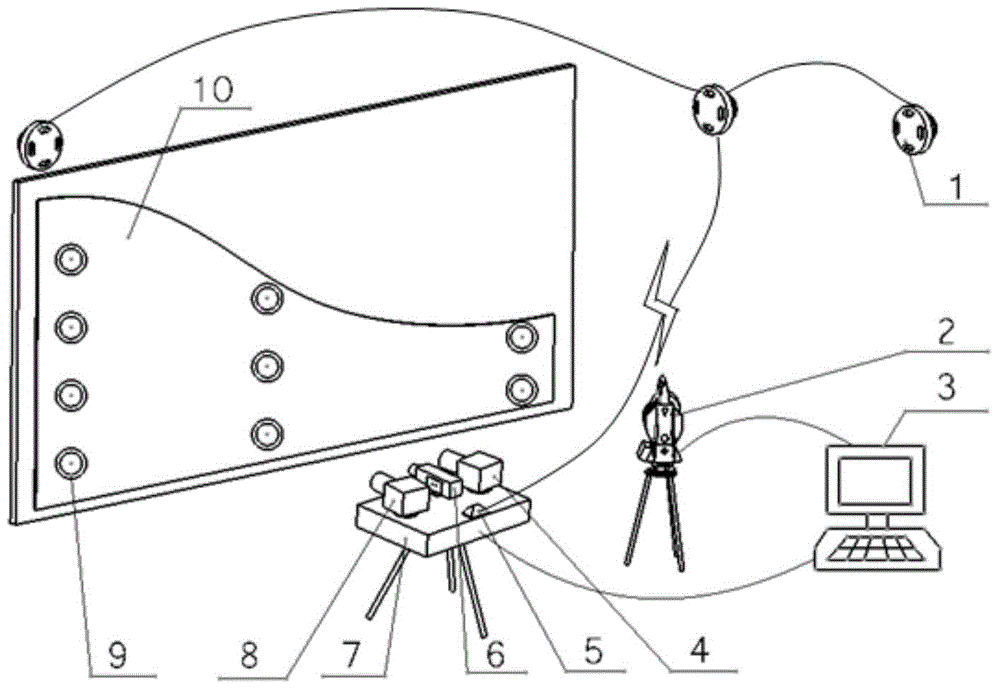

[0035] The visual measurement system for the geometric parameters of large composite panels is based on the binocular vision measurement system, supplemented by a laser tracker system and an indoor Bluetooth positioning system. As shown in the attached figure, in order to facilitate the processing and assembly of large composite panels, it is necessary to figure 1 In-situ parameter measurement of large composite panels 10 . The specific process of measurement is as follows:

[0036]First, for a certain large-scale composite board 10 in the production process, it is placed in a suitable position, and a plurality of feature points are selected on its surface to paste reflective targets 9 respectively, and then the composite board is visually calibrated. First use the laser tracker 2 to measure the feature points on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com