Heat accumulating type pure air heating system

An air heating and thermal storage technology, applied in thermal storage heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of unpredictable cycle, high risk, and difficult to achieve, and achieve large thermal storage and effective work. long time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

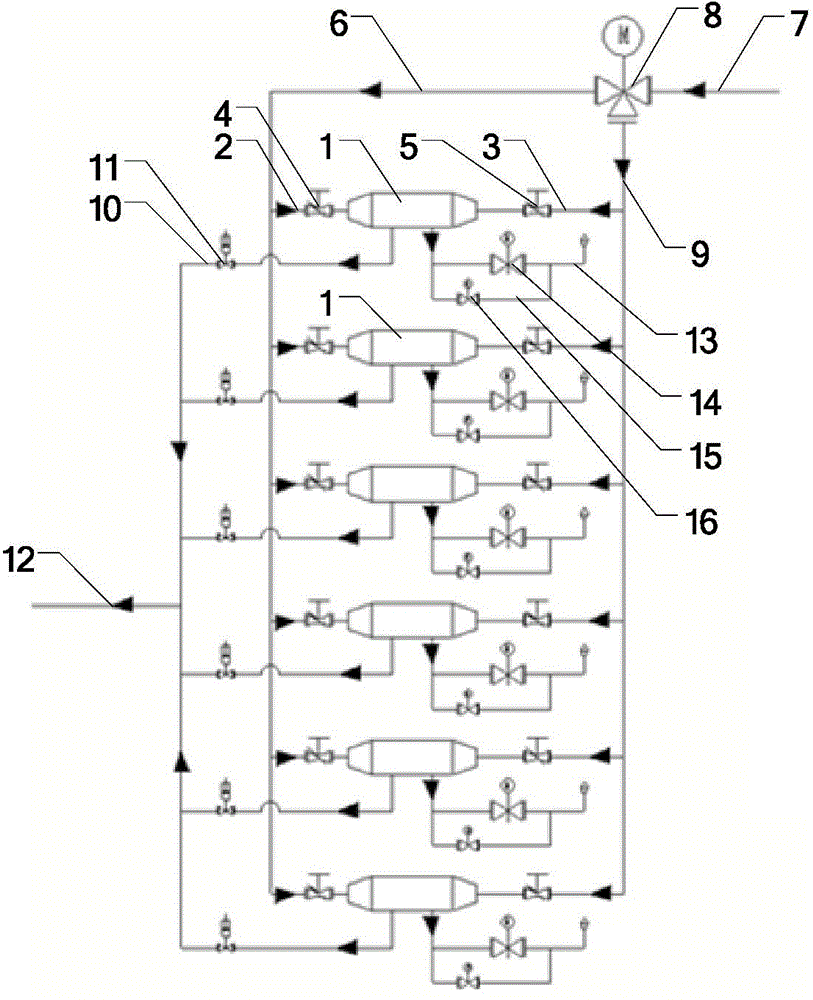

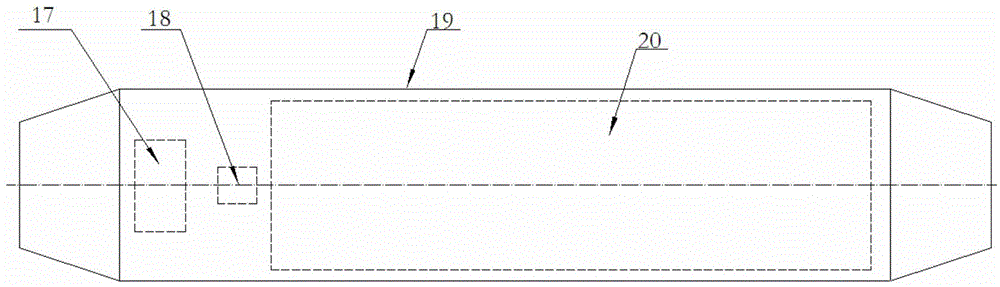

[0049] Such as figure 1 As shown, the present invention provides a regenerative pure air heating system, including: six heaters 1 arranged in parallel, each heater 1 has an effective power of about 9MW, and the heater 1 is the low line of the FD07 wind tunnel Metal sheet thermal storage heater; a first air intake pipeline, which is connected to the first air intake end (also called hot end) of the heater 1 to supply cold air to the heater 1, wherein each A heater 1 corresponds to a first air intake pipeline 3; and an air outlet pipeline, which is connected to the outlet ends of the six heaters, and mixes and outputs the hot air respectively output by the six heaters.

[0050] The present invention adopts the heater 1 in the prior art,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com