Pipe-jacking construction method for pipeline bottom grouting reinforcement

A technology of grouting reinforcement and construction method, which is applied in the direction of pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as vertical high-pressure jet grouting pile reinforcement, and achieve good economic and social benefits. The effect of outstanding benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

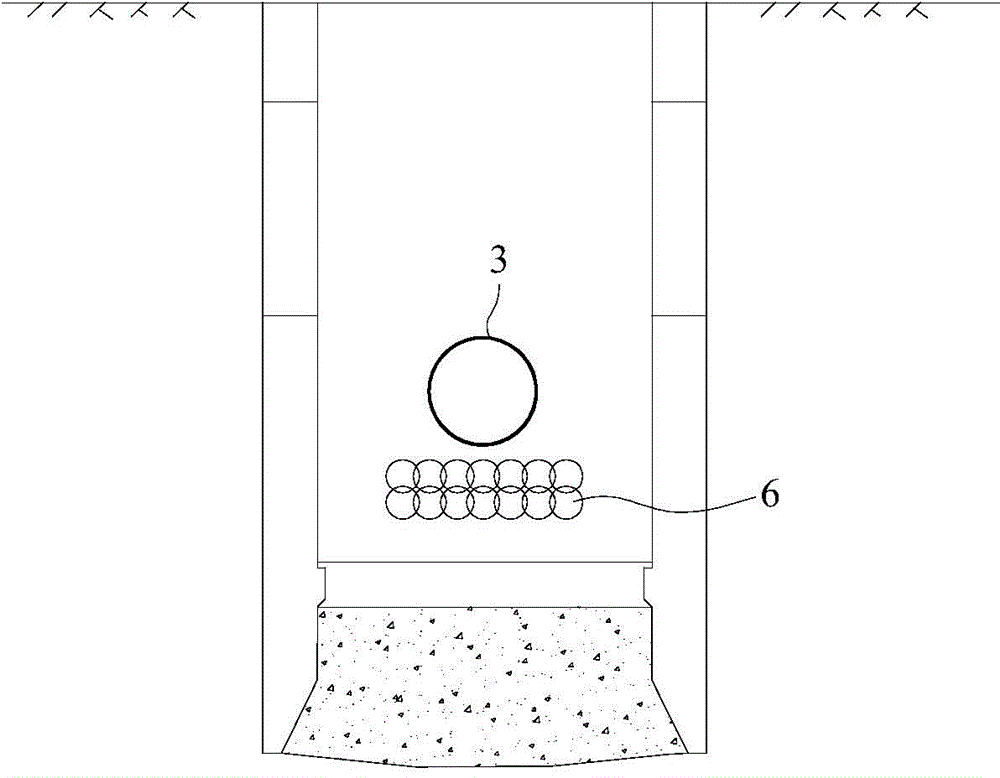

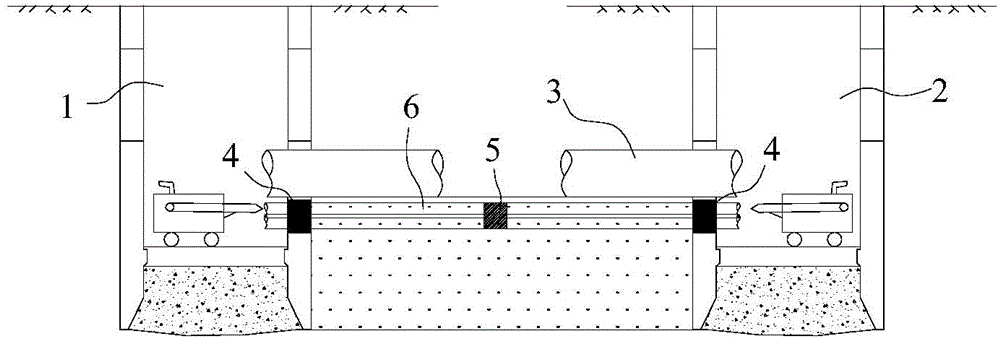

[0028] refer to figure 1 , figure 2 , the invention provides a pipe jacking construction method for reinforcing the bottom of the pipe by grouting, comprising the following steps:

[0029] A. The caisson method is used to construct the working well 1 and the receiving well 2 along the laying direction of the pipeline 3. The outer diameter of the circular working well 1 is 16.6 meters, the depth is 24.7 meters below the ground, and the concrete bottom is sealed; the outer diameter of the circular receiving well 2 is 9.6 meters , the depth is 22.5 meters underground, and the concrete bottom is sealed. A number of parallel horizontal directional holes are formed between the working well 1 and the receiving well 2 below the preset position of the pipeline 3, and DN150 pre-buried holes 4 are set at the hole forming positions of the horizontal directional holes. Prevent the hole from being tampered with during the drilling process. The working well 1 and the receiving well 2 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com