Sealing method suitable for sealing magnetic liquid under large shaft runout working condition

A magnetic liquid, a relatively advanced technology, applied in the field of magnetic liquid sealing, can solve the problems of pole tooth damage on the pole shoe, reduce sealing performance, reduce reliability, etc., to improve sealing performance, avoid impact, reduce linear speed and calorific value small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

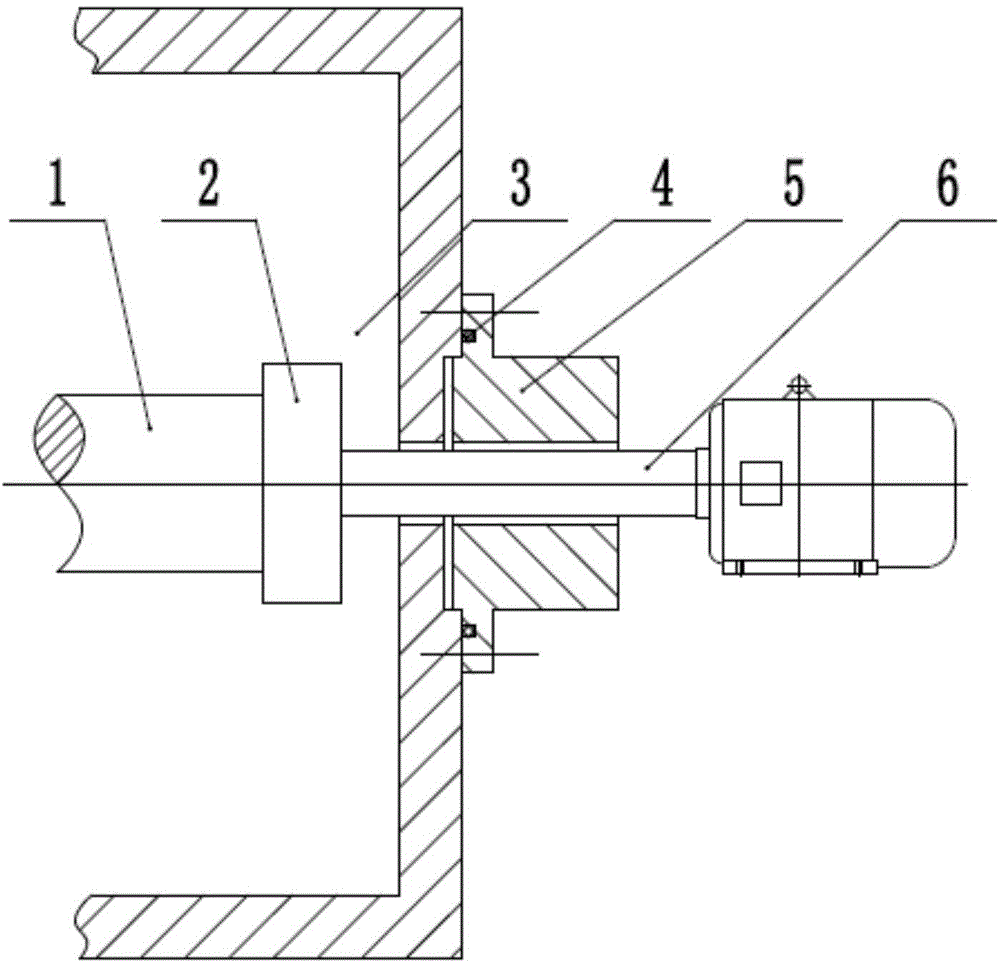

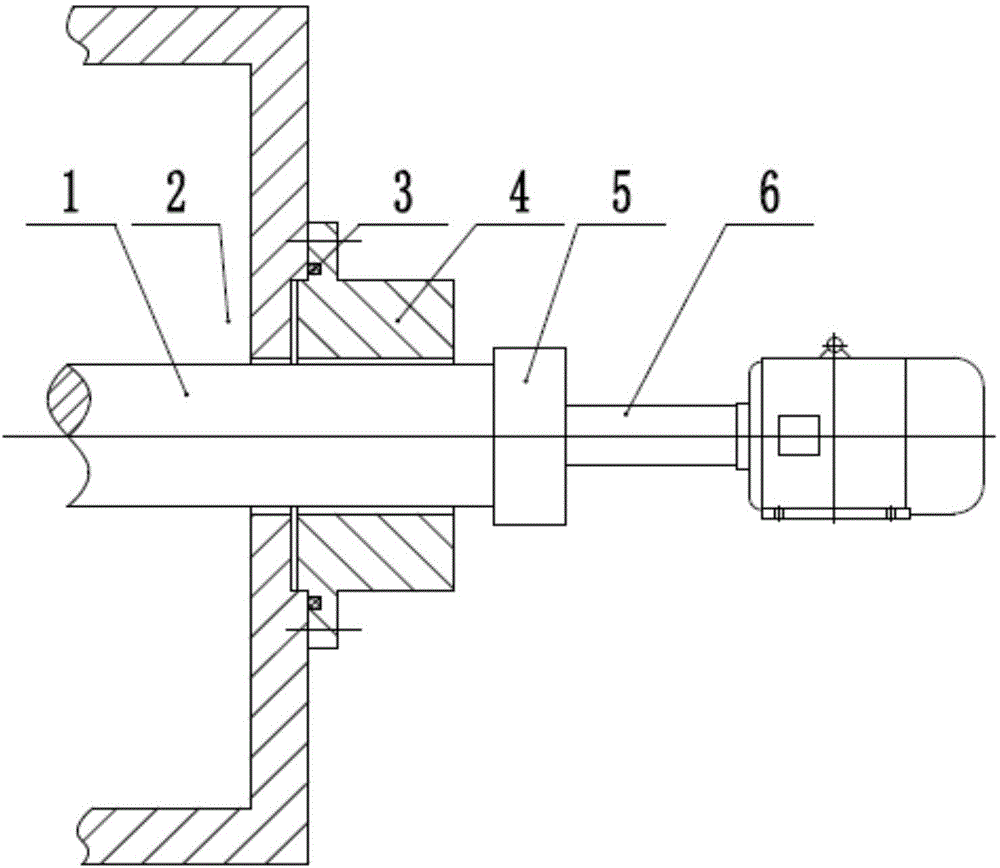

[0019] The present invention will be further described with accompanying drawing as specific embodiment:

[0020] A sealing method suitable for magnetic liquid seals under the condition of large shaft runout, the sealing method includes the following steps:

[0021] Step 1 Grinding and cleaning the positioning hole on the right end surface of the shell of the chamber 3 and the positioning stop on the left end surface of the magnetic liquid seal assembly 5;

[0022] Step 2 Install the sealing ring 4 in the sealing groove on the left end surface of the magnetic liquid sealing assembly 5;

[0023] Step 3 Install the magnetic liquid seal assembly 5 on the right end surface of the housing of the chamber 3; the magnetic liquid seal assembly 5 and the right end surface of the housing of the chamber 3 are positioned through the positioning notch; the magnetic liquid seal assembly 5 and the housing of the chamber 3 are connected by bolts fixed;

[0024] Step 4: Push the motor shaft 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com