Ball hinge capable of measuring spatial revolution angle and offset in three degrees of freedom

A technology of rotation angle and degree of freedom, applied in the field of measurement, can solve the problems of high cost, difficulty in guarantee, and difficulty in direct application, etc., and achieve the effect of reduced installation space requirements, simple algorithm, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

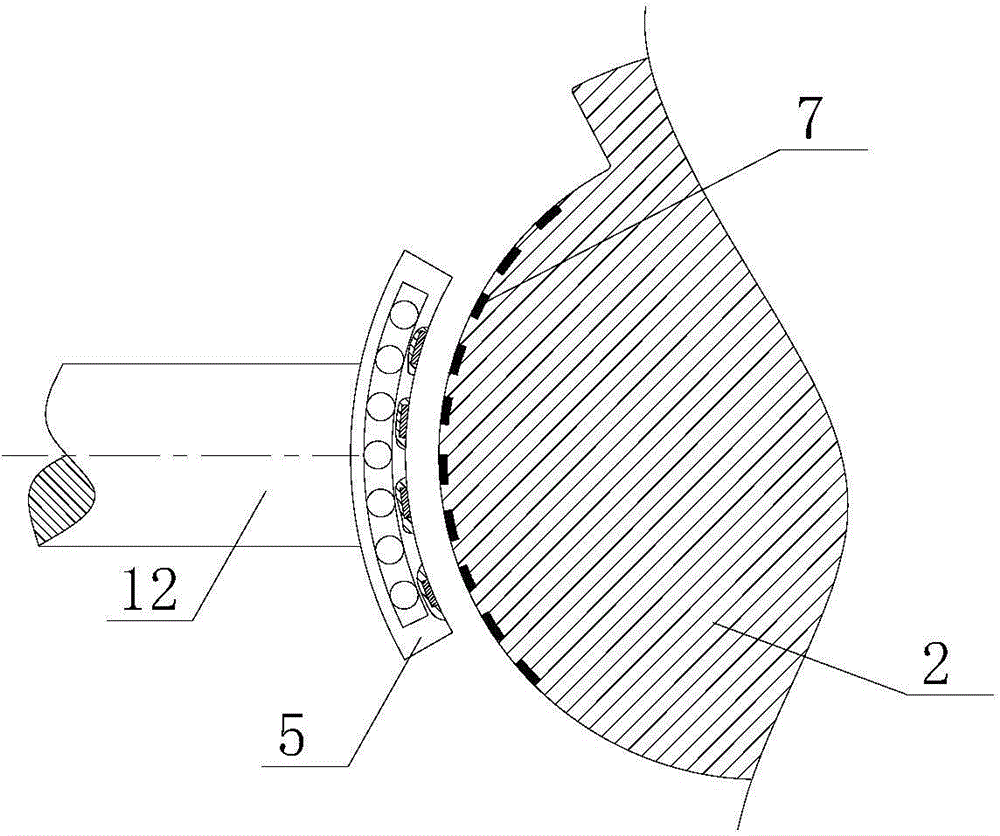

[0030] Such as figure 1 and 2 As shown, a ball hinge capable of measuring three-degree-of-freedom rotation angle and offset in space includes a ball socket base 1, a ball head 2, a ball head connecting rod 3, an output rod 4, an arc-shaped slider 5, and a pin shaft 12 And the space rotation angle measurement device; The space rotation angle measurement device includes a capacitance electrode array, a second capacitance electrode group, a third capacitance electrode group, a first capacitance sensing electrode pair, a second capacitance sensing electrode pair, a third capacitance sensing Electrode pair, fourth capacitive sensing electrode pair, fifth capacitive sensing electrode pair, sixth capacitive sensing electrode pair, seventh capacitive sensing electrode pair, eighth capacitive sensing electrode pair, ninth capacitive sensing electrode pair , the tenth capacitive sensing electrode pair, the eleventh capacitive sensing electrode pair and the twelfth capacitive sensing el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com