High-power centrifugal fan with adjustable supply air rate

A centrifugal fan, high-power technology, used in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of increased installation and production costs, inability to start the motor, low work efficiency, etc., to save production costs and installation. Cost, preventing failure to start, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

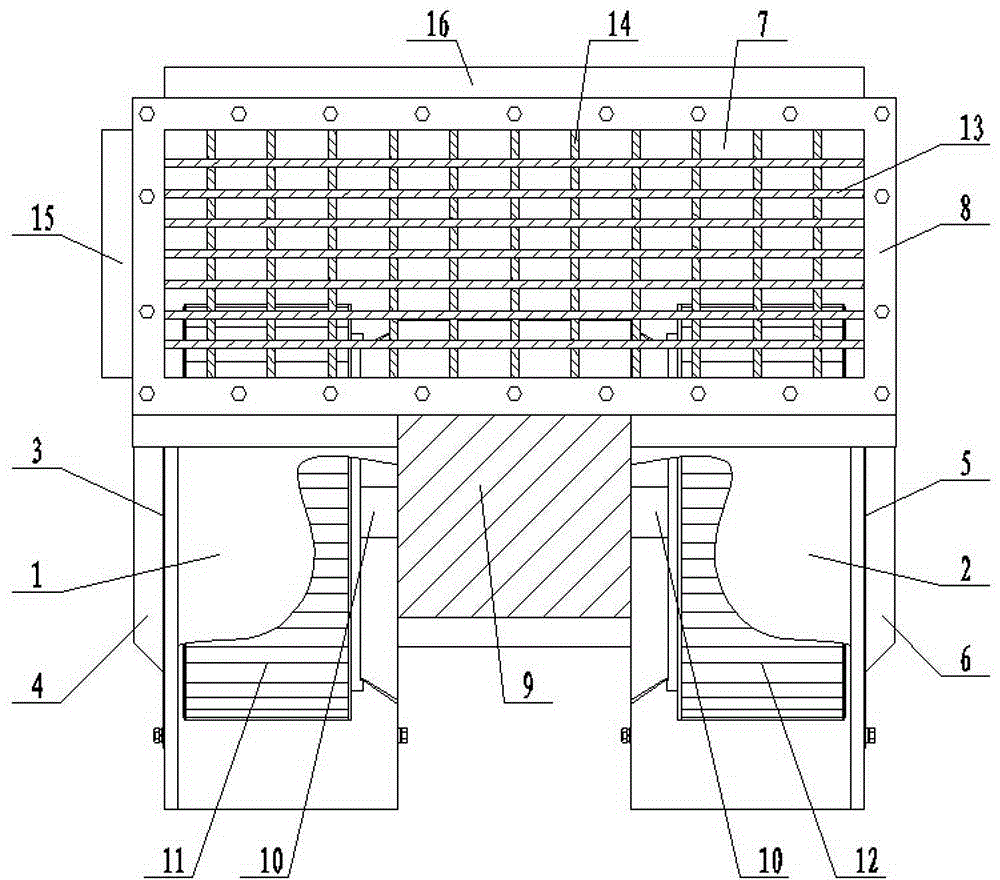

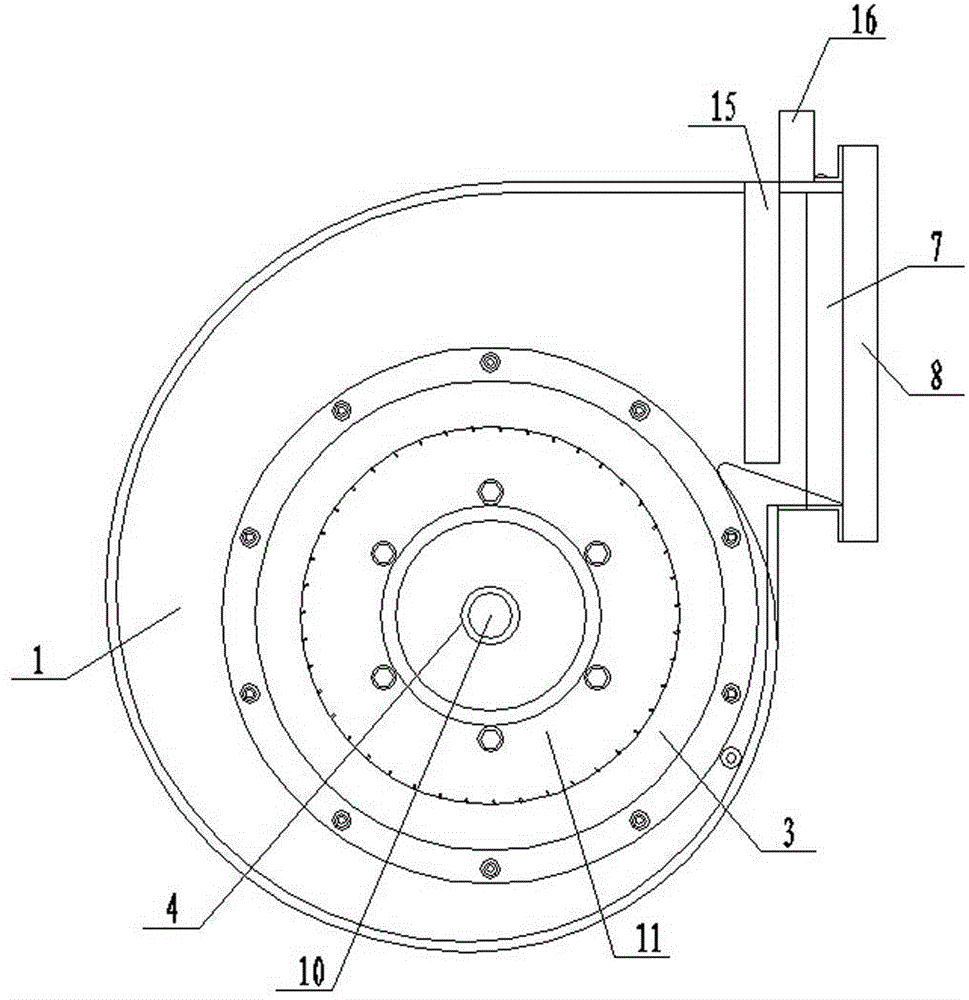

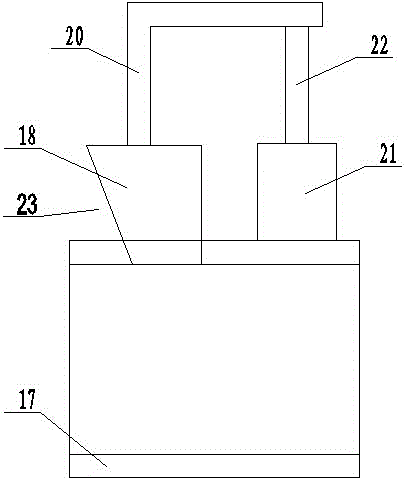

[0012] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0013] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the integrated high-power centrifugal ventilation with adjustable wind speed

[0014] machine, including: a left volute 1 and a right volute 2, a left air inlet 3 and a left motor shaft mounting bracket 4 are arranged on the left side of the left volute 1, and a The right air inlet 5 and the right motor shaft mounting bracket 6 are provided with an air outlet 7 and an air outlet fixing flange 8 on the end faces of the left volute 1 and the right volute 2, and the air outlet 7 is connected with the left air inlet at the same time. The tuyere 3 communicates with the right air inlet 5, and a double-shaft three-phase asynchronous motor 9 is arranged between the left volute 1 and the right volute 2, and one end of the motor shaft 10 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com