Water-rich sandy cobble stratum shield short-range underneath pass rigid bridge construction method

A technology of bridge construction and sand and pebbles, which is applied in basic structure engineering, earthwork drilling, soil protection, etc., can solve the problems of high labor intensity, high cost, and large engineering volume, and achieve reasonable grouting parameters and low cost , The effect of low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] This embodiment is a construction method of a shield tunneling under a rigid bridge in a water-rich sand and pebble stratum at a short distance. The method is as follows:

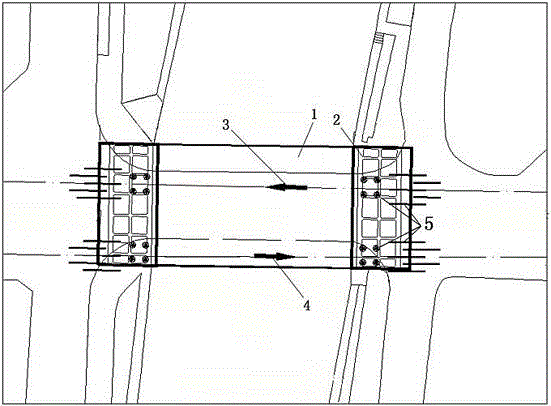

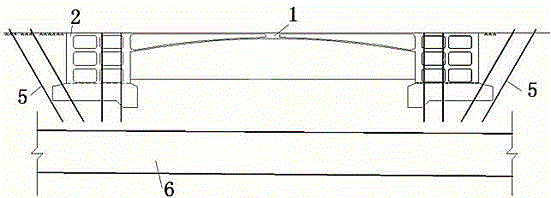

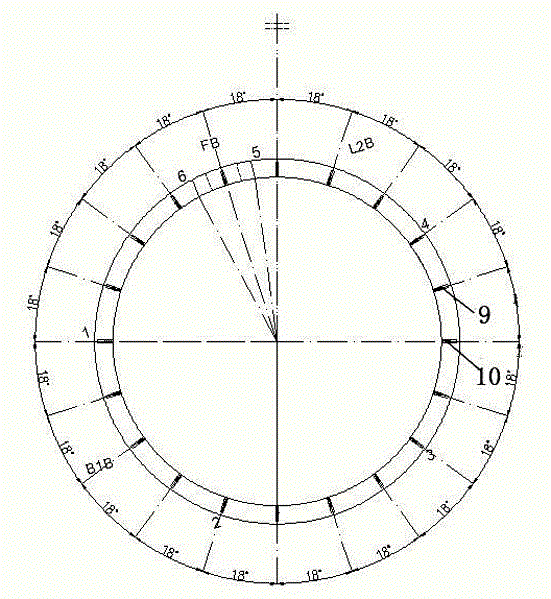

[0028] The first step is to pre-reinforce the abutment with grouting, and the abutment is reinforced with sleeve valve pipe grouting. On each side of the single-line abutment, 4 vertical holes and 5 oblique holes are set along the center line. The vertical distance between the bottom of the drilled hole and the top of the tunnel About 1.2m, use a grouting machine to inject pure cement slurry through the pre-embedded sleeve valve pipe to evenly reinforce the bottom of the abutment. The four vertical holes mentioned above have a longitudinal spacing of 2.7m, a horizontal spacing of 3m, and a hole depth of 12.8m. , 1.8m on one side and 1.2m on the other side, respectively, on both sides of the center line of the line, 4 vertical holes and 5 inclined holes are arranged on each side of the abutment; two ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com