Thin-walled sleeve steel bar lap connection member with helical reinforcement restraint

A technology of lap joints and spiral ribs, which is applied in the direction of building components, structural elements, building reinforcements, etc., can solve the problems of weakened energy dissipation capacity of the connection position, high rigidity of the sleeve connection part, high construction and installation accuracy, etc., to achieve Improve concrete deformation ability and ductility performance, improve efficiency and quality, and facilitate the effect of grouting installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

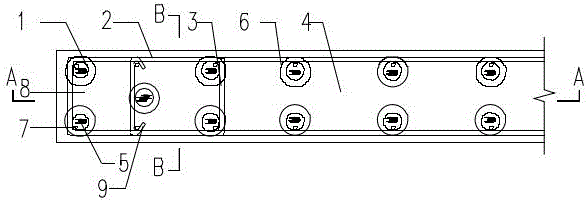

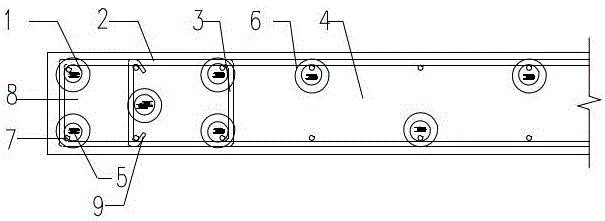

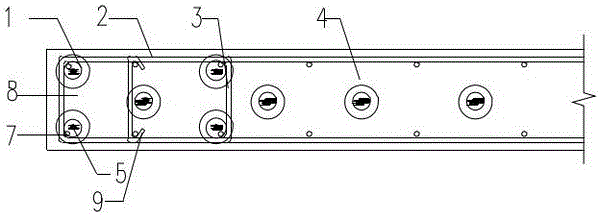

[0015] Attached below figure 1 to attach Figure 5 And the specific embodiment will further illustrate the present invention:

[0016] The thin-walled sleeve steel bar lap connection member with spiral reinforcement constraints is composed of the upper concrete shear wall member 4 and the lower concrete shear wall member 12, and the floor 11 is between the upper and lower prefabricated concrete shear wall members; the upper floor The concrete shear wall member 4 includes a thin-walled sleeve 1 and a spiral stirrup 6, and a thin-walled sleeve 1 is buried at the lower end of the upper concrete shear wall member 4, and the thin-walled sleeve 1 is covered with a spiral stirrup 6; the thin-walled sleeve 1 The upper and lower ends of the upper and lower ends are provided with sealing rubber plugs 13 with round holes, and the vertical steel bars 7 of the upper precast concrete shear wall extend into the thin-walled sleeve 1 through the upper end round holes; the lower concrete shear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com