Construction method and equipment for mounting vertical-precipitation well point pipe

A construction method and technology of dewatering wells, which are applied in infrastructure engineering, construction, etc., can solve problems such as sand filter material gradation or uneven input, affecting drainage effect, and low construction efficiency, so as to improve the construction operating environment and reduce construction costs. Low labor intensity and low construction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

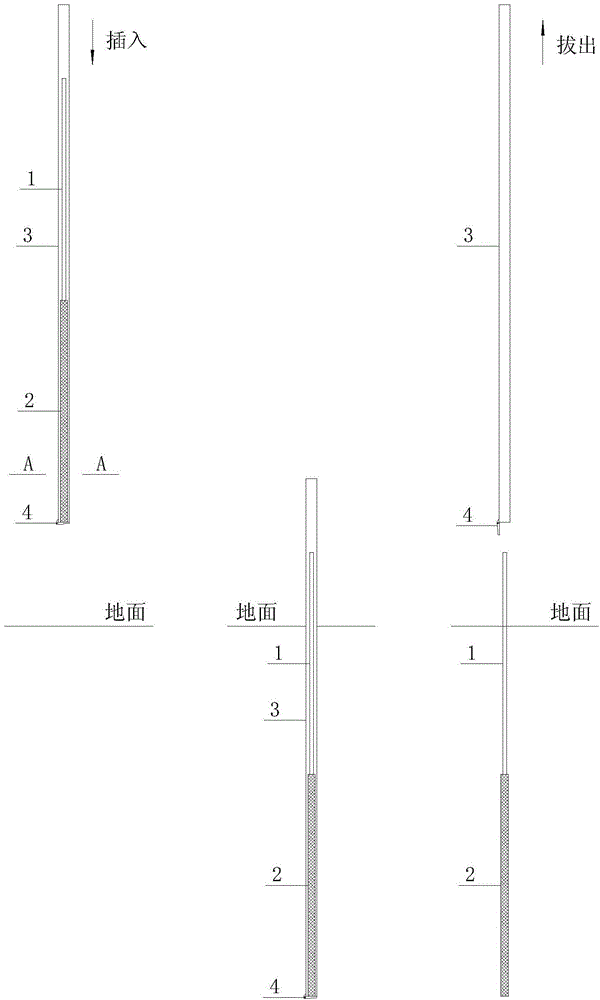

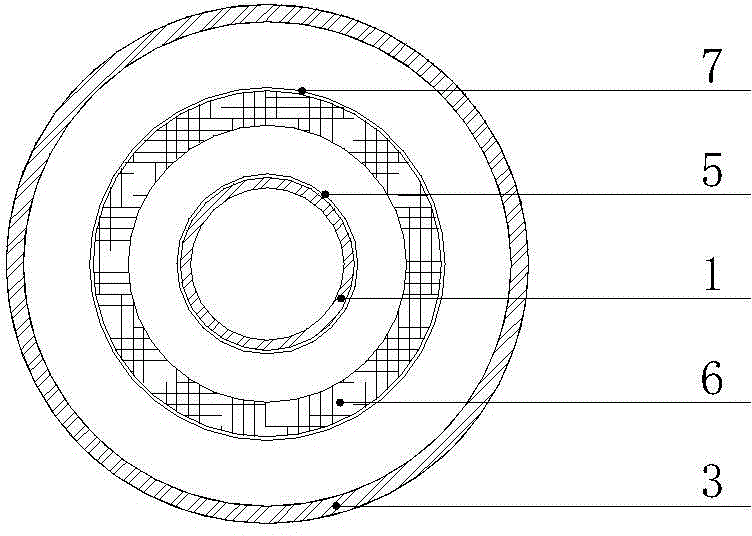

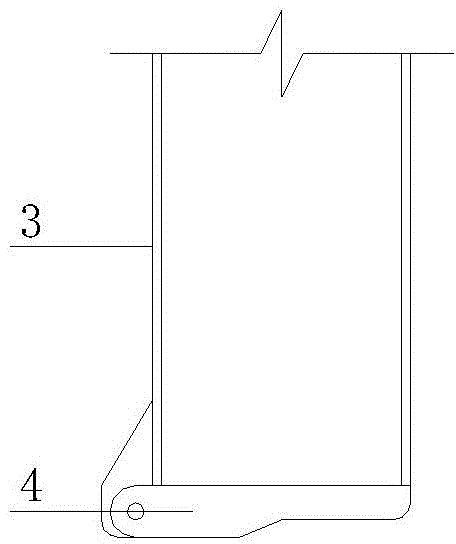

[0046]The technical scheme adopted in the present invention is: use the tubular plastic blind ditch 2 of circular section as the filter material of the dewatering well point, fix the plastic blind ditch 2 on the front end of the well point pipe 1, and put the well point pipe 1 into the casing of the special equipment Inside the pipe 3, a movable spud shoe 4 is installed at the bottom of the casing 3, so that the movable spud shoe 4 is in a closed state to block the casing 3, and the casing 3 is squeezed into the formation by means of vibration or static pressure, and the casing is pulled out. When the pipe 3 is in the open state, the movable spud shoe 4 is in the open state, and the well point pipe 1 is left in the soil, and the periphery of the well point pipe 1 is sealed with clay, and the installation of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com