An energy-saving and enhanced refining method for producing sticky pulp by composite pretreatment

A pretreatment and refining technology, applied in pulp beating/refining method, fiber raw material processing, paper, etc., can solve the problems of long processing time, high-speed continuous production, low biological enzyme treatment efficiency, and reduced physical strength of paper. , to overcome the long processing time, improve the physical properties of fiber into paper, and improve the physical properties of paper.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

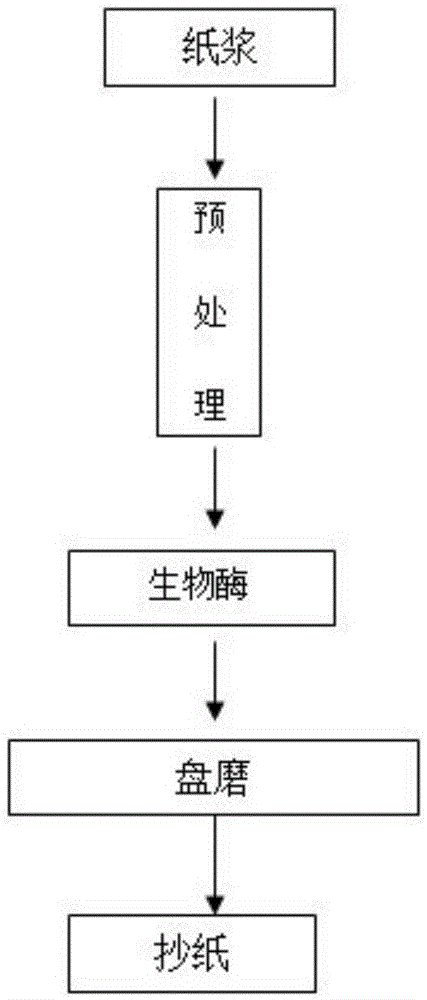

Method used

Image

Examples

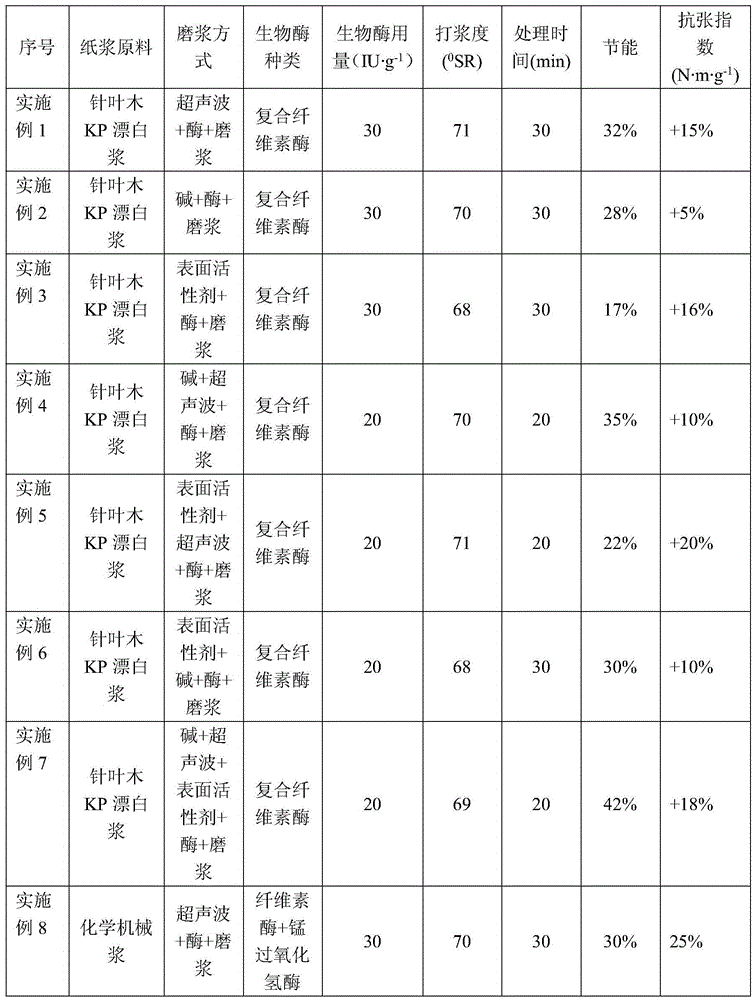

Embodiment 1

[0024] Dissolve the pulp fiber in water, place it in an ultrasonic oscillator, and stir it: long fiber KP bleached pulp concentration is 4.2%, pH=7.7, temperature 23°C, ultrasonic power 250W, ultrasonic frequency 40kHz, processing time 5min will be processed After adding 30 IU / g of cellulose complex enzyme to the slurry, the temperature is 40°C, pH=6.5, the slurry concentration is 4.2%, and treated for 30 minutes; PFI refining to 71°SR. The energy consumption of pulp is saved by 32%, and the tensile index is increased by 15%.

Embodiment 2

[0026] Dissolve the pulp fiber in water, add sodium hydroxide aqueous solution for pretreatment: the concentration of long fiber KP bleached pulp is 6%, the dosage of sodium hydroxide is 0.5%, the temperature is 35°C, and the treatment time is 10 minutes; add cellulose to the treated pulp Complex enzyme 30IU / g, temperature 40°C, pH=6.5, slurry concentration 4.3%, treatment for 30min; PFI refining to 70°SR. The energy consumption of pulp is saved by 28%, and the tensile index is increased by 5%.

Embodiment 3

[0028] Dissolve pulp fiber in water, add surfactant pretreatment: long fiber KP bleached pulp concentration is 6%, pH=7.2, temperature 25°C, surfactant dosage 0.15%, stirring treatment for 15min; surfactant is carboxymethyl Base cellulose: cationic starch: sodium dodecylbenzenesulfonate = 1:1:0.2; add cellulose compound enzyme 30IU / g to the treated pulp, temperature 40°C, pH=6.5, pulp concentration 4.3%, treat 30min; PFI refining to 68°SR. The energy consumption of pulp is saved by 17%, and the tensile index is increased by 16%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com