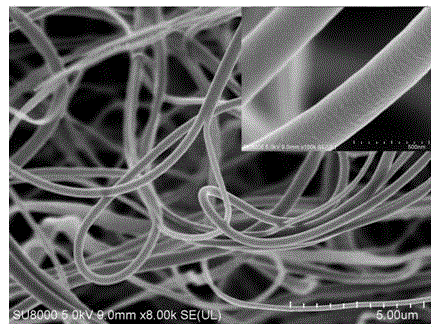

Low-density SiC nanofibers and preparation method thereof

A nanofiber, low-density technology, applied in the field of high-performance inorganic functional material preparation, can solve the problems of high requirements on equipment, high vacuum degree, and complicated equipment, and achieves low equipment requirements, uniform distribution, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Add 2.8 grams of polyacrylonitrile (PAN, molecular weight 22600) into 16 ml of N,N-dimethylformamide (DMF), stir well to form solution A; take another 1.5 ml of tetraethyl orthosilicate (TEOS) and add In 6 ml of DMF, slowly add 0.2 ml of glacial acetic acid dropwise to the mixed solution, and fully stir to form solution B; slowly add solution B to solution A, mix evenly to obtain a clear and transparent solution; after aging for 1 hour, start spinning, Electrospinning conditions are as follows: adjust the distance between the needle tip of the syringe and the receiving plate to 12 cm, set the high-voltage DC power supply voltage at 20 kV, and set the propulsion speed of the micro-syringe pump at 0.8 ml / hour; after spinning, take Precursor samples on the lower receiver plate. The precursor was placed in a tube furnace and calcined at 1390°C for 6 hours in an argon atmosphere with a heating rate of 5°C / min; then baked at 650°C for 4 hours in an oxygen atmosphere at a heat...

Embodiment 2

[0031]Add 1.4g of polyacrylonitrile (PAN, molecular weight 22,600) into 10ml of N,N-dimethylformamide (DMF), stir well to form solution A; In 10 ml of DMF, slowly add 0.4 ml of glacial acetic acid dropwise to the mixture, and stir fully to form solution B; slowly add solution B to solution A, mix well to obtain a clear and transparent solution; after aging for 1 hour, start spinning, Electrospinning conditions are as follows: adjust the distance between the needle tip of the syringe and the receiving plate to 12 cm, set the high-voltage DC power supply voltage at 20 kV, and set the propulsion speed of the micro-injection pump at 1 ml / hour; after spinning, take Precursor samples on the lower receiver plate. The precursor was placed in a tube furnace and calcined in an argon atmosphere at 1300°C for 15 hours with a heating rate of 5°C / min; then calcined in an oxygen atmosphere at 650°C for 4 hours at a heating rate of 5°C / min; the above samples were After cooling to room temper...

Embodiment 3

[0033] Take 1.4 grams of polyvinyl alcohol (PVA, molecular weight 90,000) and add it to 10 milliliters of absolute ethanol, stir well to form solution A; take another 1.5 milliliters of tetraethyl silicate (TEOS) and add it to 6 milliliters of absolute ethanol, slowly add to Add 0.2 milliliters of glacial acetic acid dropwise to the mixed solution, stir well to form solution B; slowly add solution B to solution A, mix well to obtain a clear and transparent solution; after aging for 0.5 hours, start spinning, and the electrospinning conditions are as follows: The distance between the needle tip of the syringe and the receiving plate is 12 cm, the high-voltage DC power supply voltage is set at about 22 kV, and the propulsion speed of the micro-injection pump is set at 1.2 ml / hour; after spinning, remove the precursor on the receiving plate object samples. The precursor was placed in a tube furnace and calcined at 1350°C for 5 hours in an argon atmosphere with a heating rate of 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com