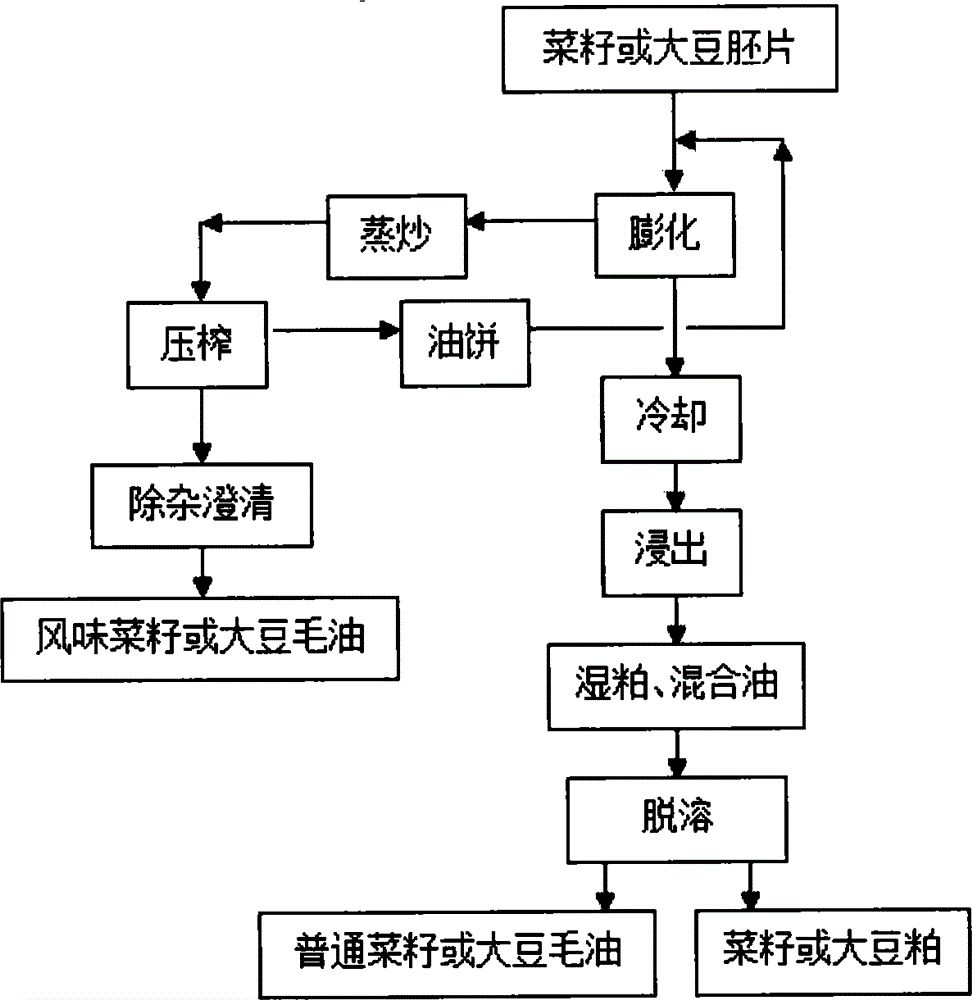

Processing method for simultaneously producing squeezed flavor oil and leaching ordinary oil

A processing method and flavor oil technology, applied in the direction of fat oil/fat production, fat generation, edible oil/fat, etc., can solve the problems of waste, low oil yield, residual oil residue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Under the conditions of 110°C and 12MPa, expand the rapeseed embryo flakes for 0.5min, then steam and fry the expanded rapeseed material at 115°C for 0.2h, and then press at 126°C for 10min to obtain pressed flavor rapeseed Crude oil (impurity 0.4%) and rapeseed oil cake containing 35.8% oil; then, the obtained rapeseed oil cake is entered into an extruder and mixed with some unsteamed rapeseed embryo flakes, then cooled to 55°C after puffing, Leaching by organic solvent, the leaching conditions are: temperature 50°C, time 40min, solvent ratio 0.8, and finally desolvation: the soybean meal discharge temperature (DT103°C, DC36°C), precipitating pressure (DT: vacuum degree 18mba, DC: Pressure 5.3KPa)), mixed oil precipitating temperature (first steaming oil temperature 56°C, second steaming oil temperature 100°C, stripping oil temperature 100°C), to obtain leached common rapeseed crude oil (residual solvent 60ppm) and rapeseed Seed meal (330ppm residual solvent, 0.7% oil,...

Embodiment 2

[0026] Under the conditions of 118°C and 16MPa, expand the rapeseed embryo flakes for 1min, steam and fry the expanded rapeseed material at 150°C for 0.5h, then press at 160°C for 5min, and obtain pressed flavor rapeseed crude oil after removing impurities (impurity 0.3%) and rapeseed oil cake containing 28.6% oil; then the obtained rapeseed oil cake enters the puffing machine and mixes with part of the rapeseed germ slices that have not been steamed and fried, and then it is puffed and cooled to 58 ° C, passed through an organic solvent Leaching, the leaching conditions are: temperature 58°C, time 60min, solvent ratio 1.0, and finally desolvation: wherein rapeseed meal discharge temperature (DT100°C, DC40°C), precipitating pressure (DT: vacuum degree 20mba, DC: pressure 4.8 KPa), mixed oil precipitation temperature (60 ℃ of first steaming oil temperature, 105 ℃ of second steaming oil temperature, 105 ℃ of stripping oil temperature), obtain leaching common rapeseed crude oil (4...

Embodiment 3

[0028] Under the conditions of 110°C and 12MPa, after puffing the soybean germ flakes for 0.5min, steam the puffed soybean material at 116°C for 0.3h, and then press it at 126°C for 10min, and get pressed flavor soybean oil (impurity 0.5% ) and soybean oil cake containing 8.2% oil; then the obtained soybean oil cake is put into an extruder and mixed with some soybean germ flakes that have not been steamed and fried, then expanded and cooled to 55°C, and leached by an organic solvent. The leaching conditions are: The temperature is 50°C, the time is 40min, the solvent ratio is 0.8, and finally the precipitation is carried out: the soybean meal discharge temperature (DT106°C, DC36°C), the precipitation pressure (DT: vacuum degree 18mba, DC: pressure 5.5KPa), mixed oil precipitation temperature (first steaming oil temperature 55°C, second steaming oil temperature 102°C, stripping oil temperature 102°C), to obtain leached common soybean crude oil (residual solvent 55ppm) and soybea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com