Method for low temperature demulsification of thickened oil

A heavy oil, low temperature technology, applied in the field of low temperature demulsification of heavy oil, can solve the problems of high energy consumption, complex process, large fluctuation of dehydration effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: the selection of heavy oil

[0019] Composition and property analysis of typical heavy oil (take the heavy oil first station oil sample of Binnan Oil Production Plant as an example). Refer to "SH / T 0509-92 Petroleum Asphalt Component Determination Method" to analyze the crude oil group components, the results are shown in the following table.

[0020] Table 1 Contents of crude oil group components

[0021] component name asphaltenes colloid Aroma Saturation quality score 3.96% 19.59% 34.65% 39.96% sum 98.16%

[0022] Note: The content of impurities (clay particles in crude oil samples) in the above table is 1.84%

[0023] The viscosity of typical oil samples is measured by AR-G2 rheometer, and the relationship between viscosity and temperature of oil samples is obtained. Provide key basic data support for the quantitative description of demulsification by heating at elevated temperature and demulsification b...

Embodiment 2

[0030] Embodiment 2: the selection of demulsifier

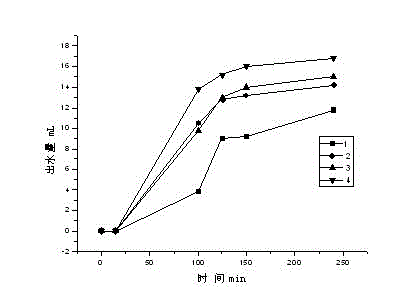

[0031] The demulsification performance of several demulsifiers was compared using the Petroleum and Natural Gas Industry Standard of the People's Republic of China, "Crude Oil Demulsifier Performance Test Method (Bottle Test Method)" (SY / T5281-2000). Three kinds of demulsifiers were selected in the experiment, namely industrial 301 oil-soluble demulsifier, industrial 401 water-soluble demulsifier and laboratory-made polyether crude oil demulsifier. The experimental results are attached image 3 ,Depend on image 3 It can be seen that for the same oil sample (oil sample from the first heavy oil station of Binnan Oil Production Plant), and other experimental conditions are the same, the dehydration rate of the laboratory-made polyether-based crude oil demulsifier is faster, while the effect of the two industrial demulsifiers is different. Not much, water-soluble demulsifiers are slightly better. The following experiments use...

Embodiment 3

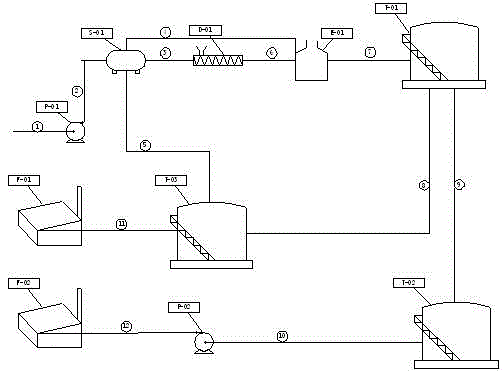

[0032] Embodiment 3: laboratory simulation demulsification process

[0033] The actual crude oil demulsification process of industrial production is simulated in the laboratory. The experimental sample is the degassed crude oil from the high-efficiency water separator at the first station of Binnan Oil Production Plant. The water content is 48%. The water content in crude oil is in accordance with GB / T 8929-88 (distillation method) for measurement (the following water content measurement method is the same). Measure 350mL crude oil sample into a 500mL beaker (diameter 8cm, height 13.8cm), put the beaker in a constant temperature water bath (60°C), and stir with a stirrer (stirring speed is 200 rpm), after the temperature is constant Add demulsifier, the amount of demulsifier is 120ppm, continue to stir for 5 minutes to fully mix the demulsifier, then stop stirring, take out the stirring paddle, seal the beaker with plastic wrap, and adjust the temperature of the constant tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com