Crude oil surface active agent as well as preparation method and application thereof

A technology of surfactants and crude oil, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of low-permeability oil reservoirs, such as cost reduction and unsatisfactory protection, so as to reduce adhesion work and increase production efficiency , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Prepare according to the following steps on the basis of 100% of the surfactant gross weight prepared:

[0042] 1. First, add 1% fatty acid diethanolamide into water to dissolve, and stir with a stirrer at a speed of 800r / min to fully mix it with water.

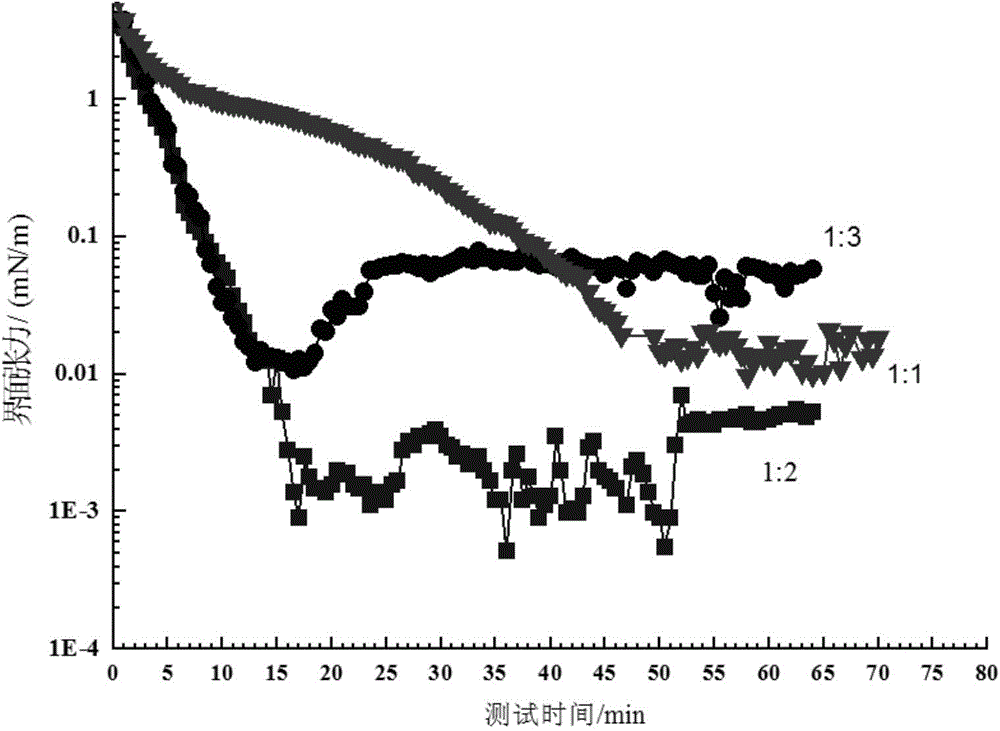

[0043] 2. After stirring evenly, add 5% polyoxyethylene fatty acid amide in turn (preparation method: 1. Use oleic acid and diethanolamine (molar ratio: 2:5) to react at a reaction temperature of 140-150°C for 3 hours to obtain oil Acid diethanolamide; 2. Use oleic acid diethanolamide and ethylene oxide (molar ratio 1:3.5) to react for 4 hours at a reaction temperature of 160-180°C to obtain polyoxyethylene fatty acid amide. Performance parameters: average Molecular weight: 500, density 1.029g / cm 3, 0.1% surface tension 28.9mN / m) and 10% heptadecyl dimethyl betaine, fully stirred for 60 minutes to form a surfactant complex solution.

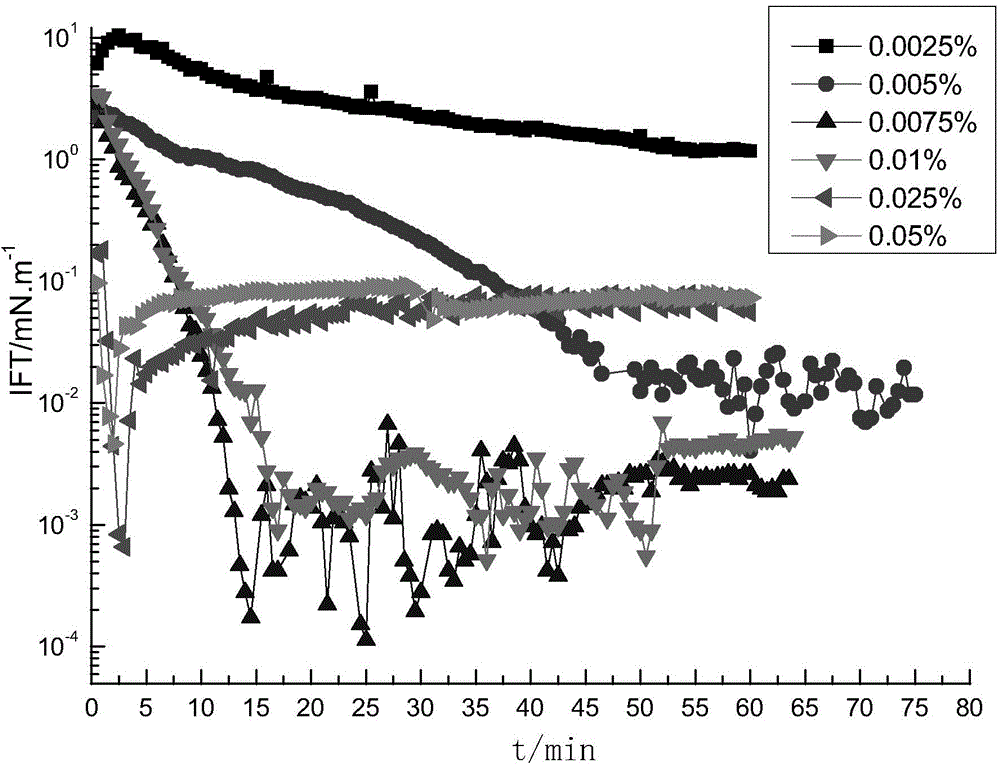

[0044] Laboratory tests show that the surfactant compound solution can form 10% wit...

Embodiment 2

[0047] 1. First, add 1% fatty acid diethanolamide into water to dissolve, and stir with a stirrer at a speed of 800r / min to fully mix it with water.

[0048] 2. After stirring evenly, add 10% polyoxyethylene fatty acid amide (prepared according to Example 1) and 20% heptadecyldimethyl betaine respectively in sequence, and stir fully for 100 minutes to form a surfactant compound solution.

[0049] Laboratory tests have shown that the surfactant compound solution can form 10% dehydrated crude oil with crude oil at 45°C in the concentration range of 0.0085% for Hainan 3 blocks of dehydrated crude oil. -3 ~10 -4 Ultra-low interfacial tension of mN / m.

Embodiment 3

[0051] 1. First, add 1.5% fatty acid diethanolamide into water to dissolve, and stir with a stirrer at a speed of 800r / min to fully mix it with water.

[0052] 2. After stirring evenly, add 8% polyoxyethylene fatty acid amide (prepared according to Example 1) and 16% heptadecyl dimethyl betaine successively respectively, and fully stir for 100 minutes to form a surfactant compound solution.

[0053] Laboratory tests have shown that the surfactant compound solution can form 10% dehydrated crude oil with crude oil at 45°C in the concentration range of 0.0082% for Hainan 3 blocks of dehydrated crude oil. -3 ~10 -4 Ultra-low interfacial tension of mN / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com