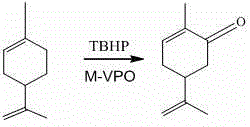

Method for realizing one-step synthesis of carvone through catalytic oxidation

A technology for catalytic oxidation and carvone, which is applied in the oxidation preparation of carbonyl compounds, organic chemistry, etc., can solve the problems of low conversion rate, environmental pollution, low selectivity, etc., and achieves high conversion rate, abundant resources and good selectivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 2.5 g V 2 o 5 , add the calculated amount of metal component precursor AgNO according to n (Ag) / n (V) =0.1 3 , placed in 40 mL of isobutanol, refluxed at 120°C for 12 h, then added H 3 PO 4 , continued to reflux at 110°C for 6 h, the obtained precipitate was filtered and washed with deionized water until neutral, dried in air at 110°C for 12 h, and then calcined in air at 400°C for 4 h to obtain dark green Ag- VPO catalyst.

[0026] Add 0.02 g of the above catalyst, 5 mL of acetonitrile, 0.5 mL of limonene and 2 mL of tert-butyl hydroperoxide into a 100 mL round bottom flask, heat in a constant temperature oil bath at 82 °C, magnetically stir at 650 r / min, and reflux for 10 h under condensation. Sampling after the reaction, analyzed by gas chromatography, showed that the conversion rate of limonene was 84.3%, the selectivity of carvone was 25.2%, and the selectivity of carveol / epoxidized limonene was 30%.

Embodiment 2

[0028] Catalyst preparation, the synthesis method of carvone, the amount of feed, and the reaction conditions are basically the same as in Example 1, except that the amount of limonene added is 0.75 mL. At this time, the conversion rate of limonene is 68.3%. Carvone The selectivity is 22.8%.

Embodiment 3

[0030] Weigh 2.5g V 2 o 5 , add the calculated amount of metal component precursor ZrOCl according to n (Zr) / n (V) =0.1 2 ·8H 2 O, placed in 40 mL of isobutanol, refluxed at 120°C for 12 h, then added H 3 PO 4 , continue to reflux at 110°C for 6 h, filter and wash the obtained precipitate with deionized water until neutral, and dry in air at 110°C for 12 h; then roast at 400°C in air for 4 h to obtain dark green Zr- VPO catalyst.

[0031] Using the prepared Zr-VPO as a catalyst, catalytic oxidation is used to synthesize carvone. The reaction conditions are the same as in Example 1. After the reaction, samples are taken, and analyzed by gas chromatography. The conversion rate of limonene is 88.9%, and the selectivity of carvone is 30.0%. , the selectivity of carveol / epoxidized limonene was 31.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com