A method for enhanced adsorption of fluoride and sulfate in groundwater and recovery of ammonium sulfate

A technology of fluoride and sulfate, applied in chemical instruments and methods, ammonium sulfate, adsorption water/sewage treatment, etc., can solve unsuitable problems, achieve safe use, obvious environmental and economic benefits, and process flow simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

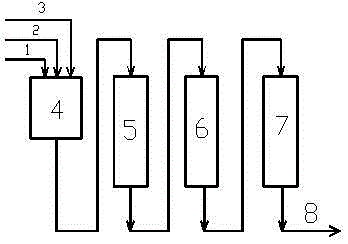

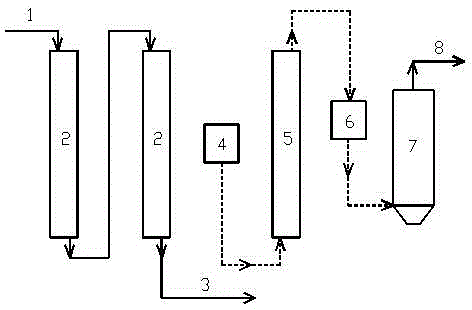

Method used

Image

Examples

Embodiment approach 2

[0036] The modified activated alumina is prepared with a lanthanum-magnesium molar ratio of 1:2, a calcination temperature of 400°C, and a calcination time of 3 hours.

[0037]Modified activated alumina adsorption column: operate at a water temperature of 15-25°C, the influent pH value is 6-8; the operating flow rate is 8m / h, the concentration of ammonia water regeneration solution is 10%, the regeneration flow rate is 8m / h, forward and backwash The flow rate is 20m / h, and the forward and backwash time is 20min.

Embodiment approach 3

[0039] The modified activated alumina is prepared with a lanthanum-magnesium molar ratio of 1:2, a calcination temperature of 500°C, and a calcination time of 4 hours.

[0040] Modified activated alumina adsorption column: operate at a water temperature of 15-25°C, the pH of the influent is 6-8; the operating flow rate is 12m / h, the concentration of the ammonia regeneration solution is 10%, the regeneration flow rate is 8m / h, forward and backwash The flow rate is 15m / h, and the forward and backwash time is 30min.

Embodiment approach 4

[0042] The modified activated alumina is prepared with a lanthanum-magnesium molar ratio of 1:1, a calcination temperature of 300°C, and a calcination time of 3 hours.

[0043] Modified activated alumina adsorption column: operate at a water temperature of 15-25°C, the pH of the influent is 6-8; the operating flow rate is 12m / h, the concentration of ammonia regeneration solution is 20%, the regeneration flow rate is 6m / h, forward and backwash The flow rate is 15m / h, and the forward and backwash time is 30min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com