Feeding and braking mechanism for material coiling

A brake mechanism and coil material technology, which is applied in the direction of coiling strips, thin material handling, transportation and packaging, etc., can solve problems such as complex structure, easy automatic loosening of coil tape, difficult adjustment of coil tightness, etc., to achieve overcoming complex effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

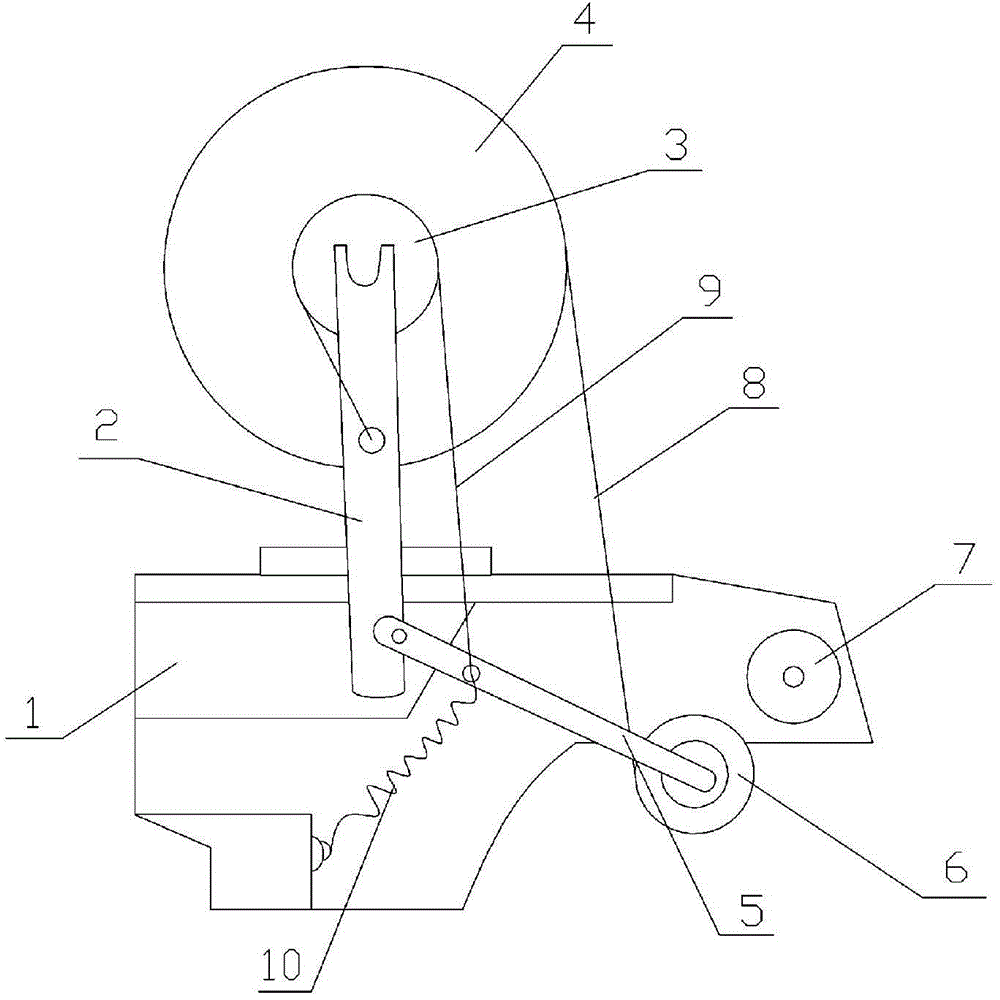

[0012] The reference signs in the accompanying drawings of the specification include: base 1, bracket 2, brake disc 3, coil material disc 4, swing lever 5, first guide roller 6, second guide roller 7, tape 8, brake band 9 , coil spring 10.

[0013] Such as figure 1 As shown, the feeding and braking mechanism of the coil includes a base 1, a bracket 2, a brake disc 3 hinged on the bracket 2, and a coil disc 4, and the coil disc 4 is coaxially arranged outside the brake disc 3 , the bracket 2 is vertically fixed on the middle part of the base 1, the outside of the bracket 2 is provided with a swing rod 5, one end of the swing rod 5 is hinged on the bracket 2 through a pin shaft, and the other end of the swing rod 5 is hinged with a first guide roller 6, The top of the first guide roller 6 is provided with the second guide roller 7 that is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com