Negative pressure pneumatic conveying rotary feeder

A negative pressure pneumatic conveying and rotary feeder technology, which is applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., can solve the problems of difficult collection, easy damage, easy suspension, etc., to reduce crushing and avoid material pressure Crushed, the effect of ensuring the degree of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

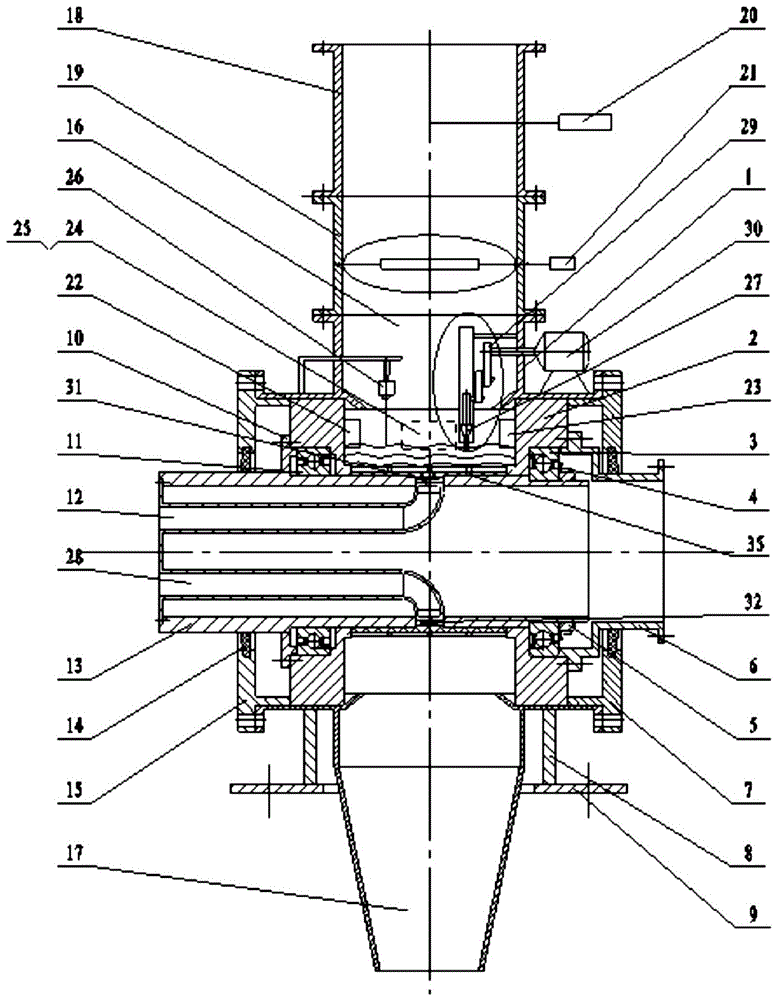

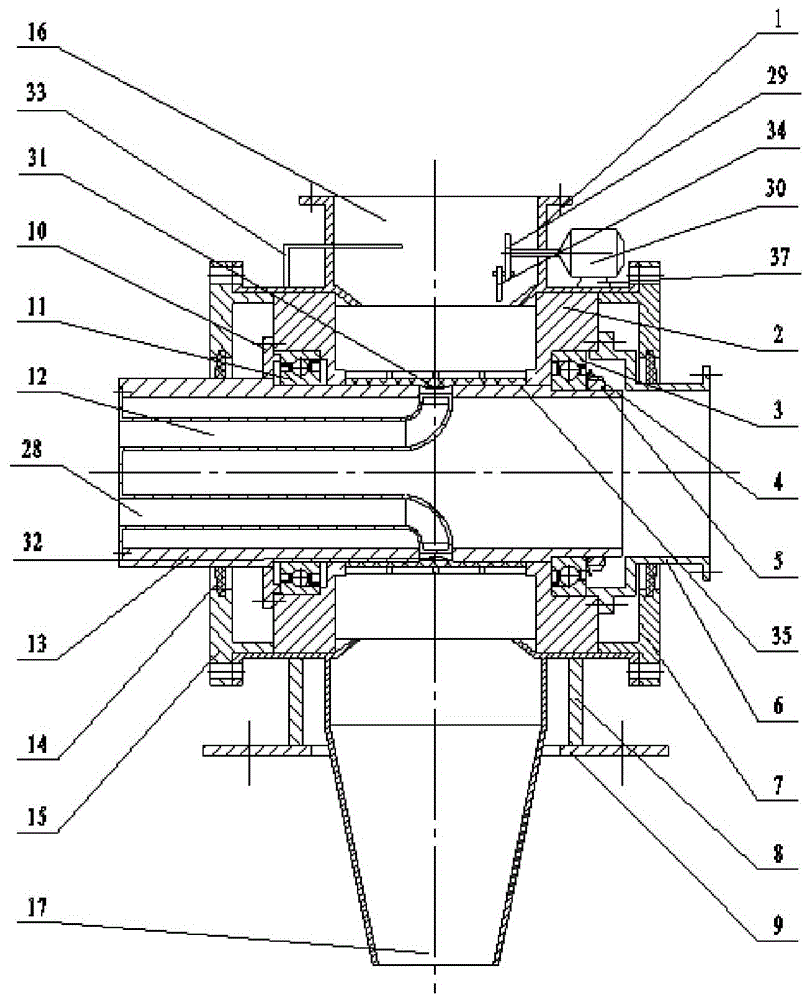

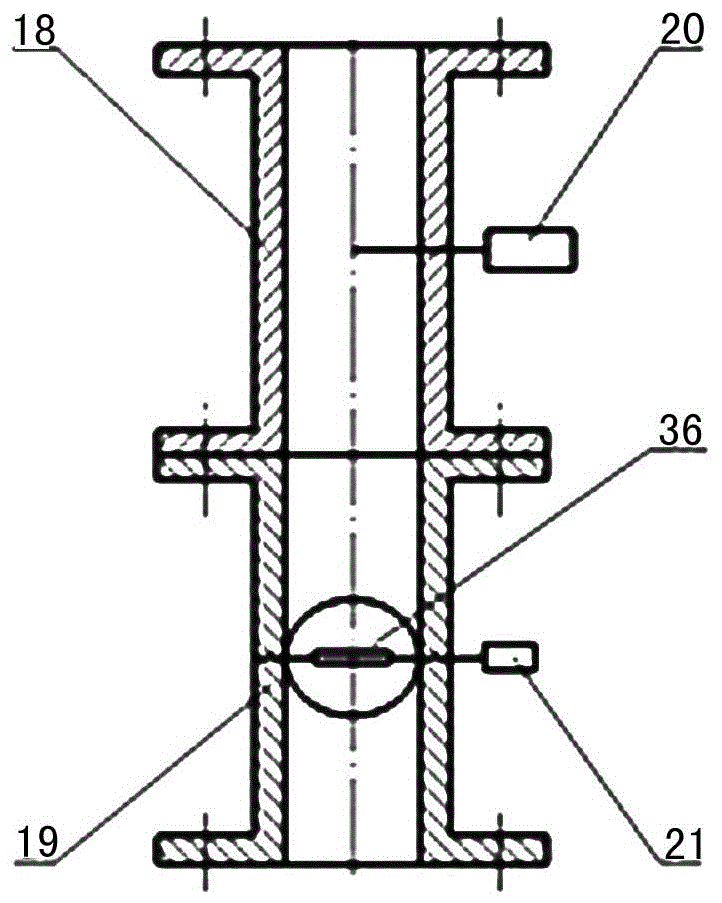

[0026] figure 1 It is an embodiment disclosed by the present invention. The negative pressure pneumatic conveying rotary feeder includes a wind speed measurement and air volume adjustment control device, a main structure of the rotary feeder, and an accurate material volume measurement system. The wind speed measurement and air volume adjustment control device includes ventilation duct I18, ventilation duct II19, wind speed sensor 20, adjusting screw 21 and air volume adjustment plate 36, and the axes of ventilation duct I18 and ventilation duct II19 are collinear during installation. The wind speed sensor 20 is fixedly installed on the side wall of the pipe Ⅰ18, and the side wall of the ventilation pipe Ⅱ19 is provided with a threaded hole to install the adjusting screw 21. The plate 36 is arranged inside the vent pipe II19, and its diameter is slightly smaller than the inner diameter of the vent pipe II19. One end of the vent pipe II19 is connected to the vent pipe I18 by bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com