A kind of 3D hollow transfer printing film and using method thereof

A transfer film and printing film technology, applied in the field of 3D hollow transfer film, can solve the problems of waste of labor efficiency, small pattern design range, easy aging, etc., to increase the imagination space, pure and bright color, good and wear-resistant. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

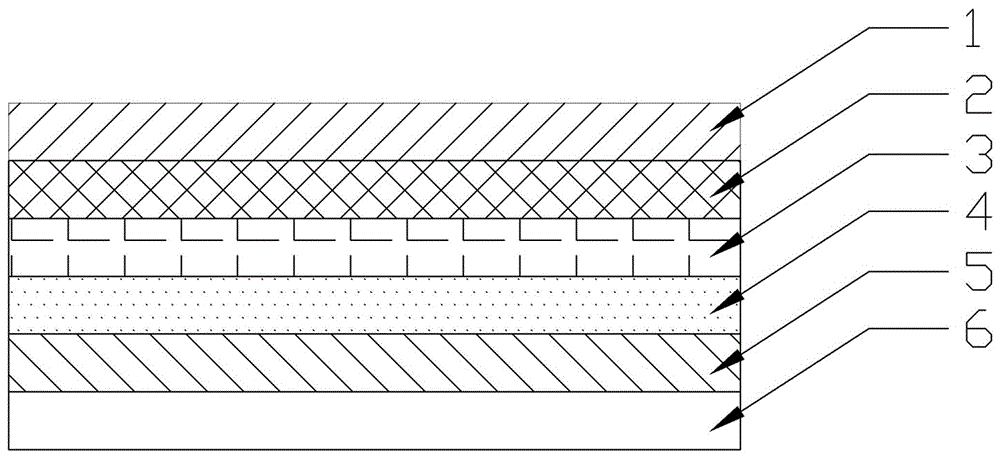

[0027] The present invention provides a 3D hollow transfer film, which includes a PP substrate layer 1, a color layer 2, a supplementary layer 3, a supporting layer 4, a bonding layer 5 and a release layer 6; the color layer 2 , supplementary layer 3, support layer 4 and bonding layer 5 are bonded from top to bottom; the color layer is attached to the lower surface of the PP substrate layer 1; the release layer 6 is attached to the lower surface of the bonding layer 5.

[0028] Color layer 2, supplementary layer 3, support layer 4 and bonding layer 5 are bonded from top to bottom and cannot be peeled off; PP substrate layer 1 is used as color layer 2, supplementary layer 3, supporting layer 4, bonding layer 5 and release layer The carrier of the type layer 6, when designing the pattern of the transfer film, use a carbon dioxide three-dimensional dynamic marking machine to engrave patterns on the color layer 2, supplementary layer 3, support layer 4, and bonding layer 5 of the t...

Embodiment 2

[0049] In this embodiment, the transfer film and its use method are the same as in Embodiment 1, the difference is that

[0050] In this embodiment, the thickness of the color layer 2 is 0.03MM, and its melting point is 190°C.

[0051] The supplementary layer 3 has a thickness of 0.03MM and a melting point of 120°C.

[0052] The thickness of the substrate layer is 0.1MM.

[0053] The support layer 4 has a hardness of 95 degrees, a thickness of 0.35MM, and a melting point of 175°C;

[0054] The bonding layer 5 has a thickness of 0.35M and a melting point of 130°C.

[0055] The thickness of the release layer 6 is 0.1MM.

Embodiment 3

[0057] In this embodiment, the thickness of the color layer 2 is 0.025MM, and its melting point is 180°C.

[0058] The supplementary layer 3 has a thickness of 0.025MM and a melting point of 130°C.

[0059] The thickness of the substrate layer is 0.15MM.

[0060] The support layer 4 has a hardness of 90 degrees, a thickness of 0.3MM, and a melting point of 160°C;

[0061] The bonding layer 5 has a thickness of 0.3M and a melting point of 120°C.

[0062] The thickness of the release layer 6 is 0.08MM.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com