Self-service printer for packaging cartons

A technology for printers and cartons, applied in printing devices, printing, etc., can solve problems such as high requirements for the cooperation between stamps and output mechanisms, high requirements for manual placement of cartons, complex shapes of control output rods, etc., to achieve mechanism continuity Strong, less space occupied, compact output mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

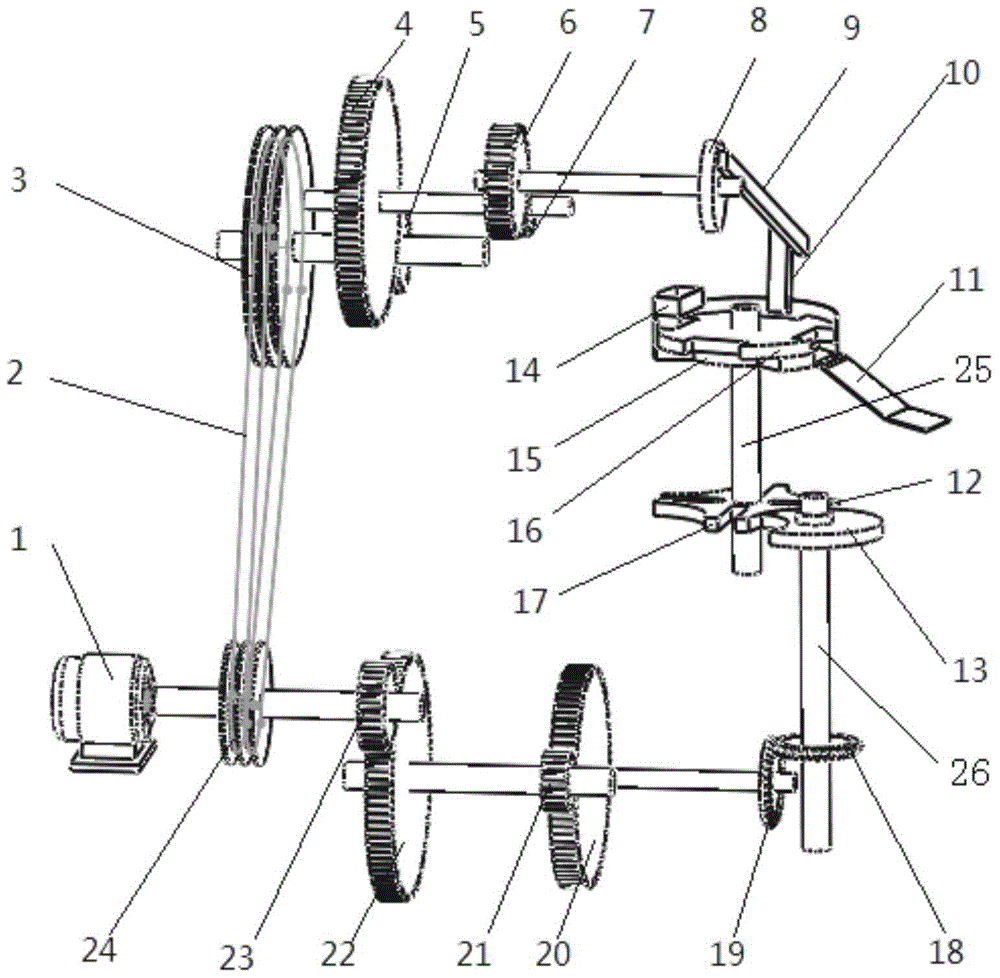

[0023] like Figure 1~5 As shown, a self-service printer for packaging cartons, which includes:

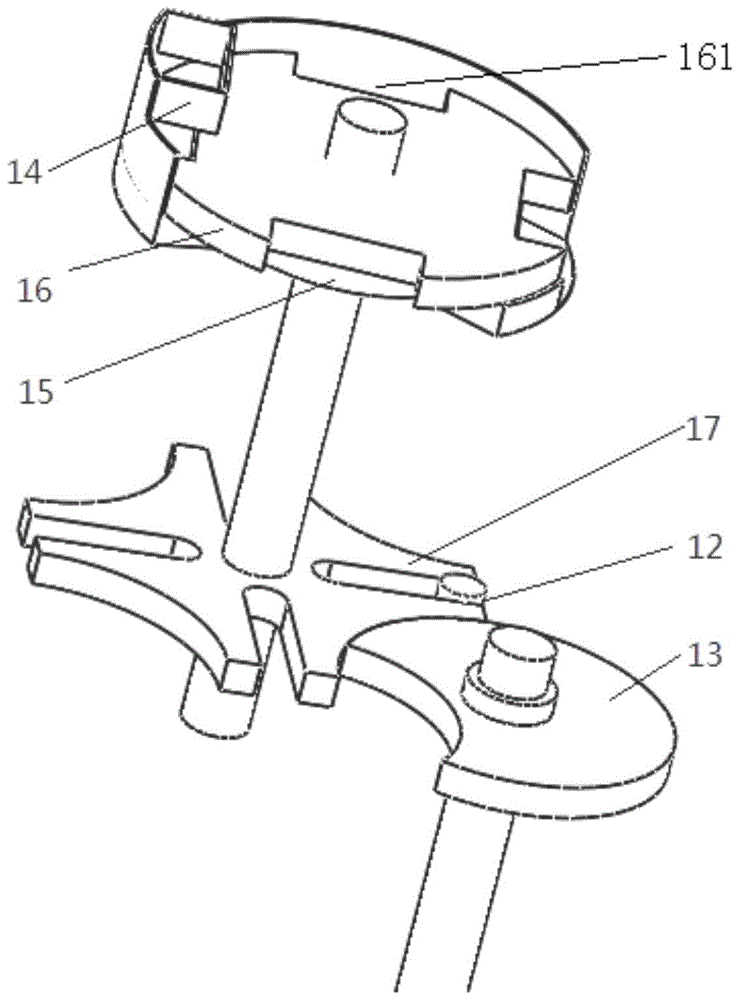

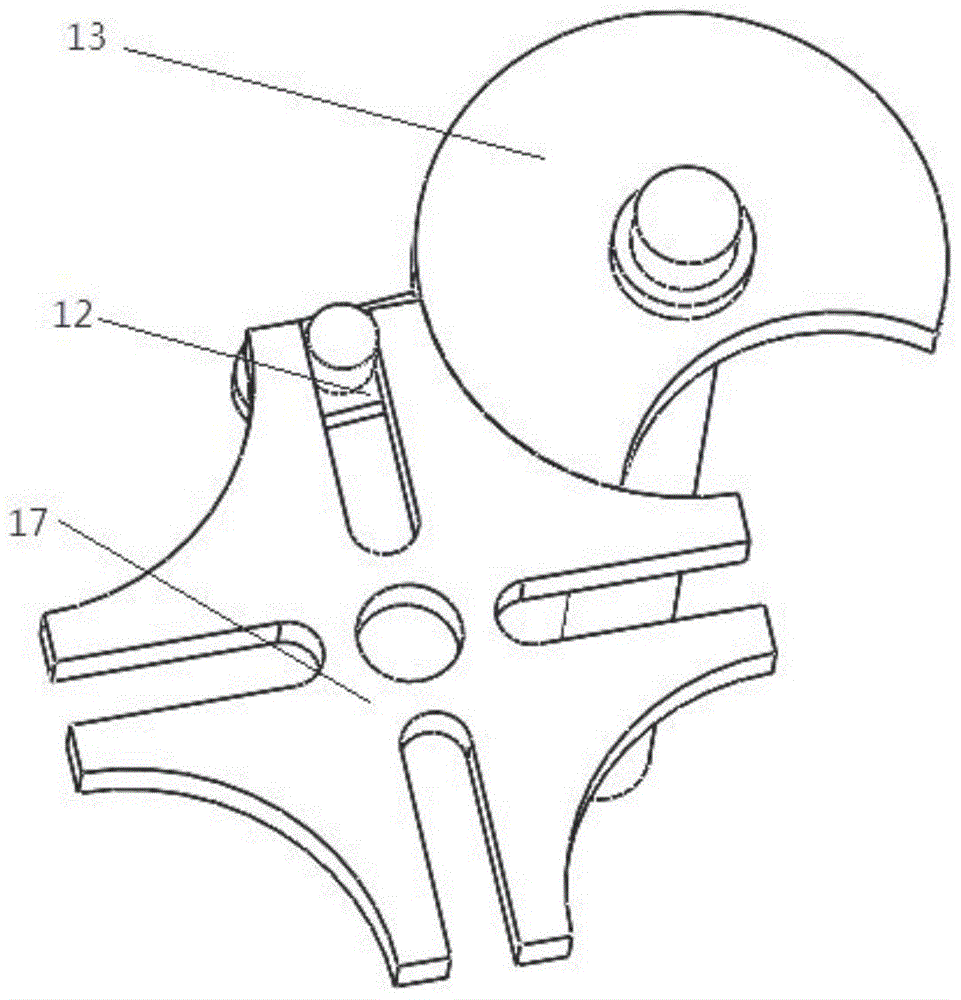

[0024] Moving disk 16, the moving disk 16 has a plurality of concave bayonets 161, during the rotation of the moving disk 16, one of the concave bayonets 161 is used as an input station, one of the concave bayonets 161 is used as a printing station, and one of the concave bayonets 161 is used as a printing station. Bayonet 161 is used as output station;

[0025] Fixed plate 15, which is located below the moving plate 16, and an output inclined part 11 is provided on the position corresponding to the output station on the fixed plate 15;

[0026] A moving disk driving device, the moving disk driving device is connected to the moving disk 16 so as to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com