Plastic particle vibratory screening device

A technology of vibrating screening and plastic particles, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of low production efficiency, large space occupation, unsuitable screening tasks with different processing capacity, etc., and achieve fast sorting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings by means of specific embodiments:

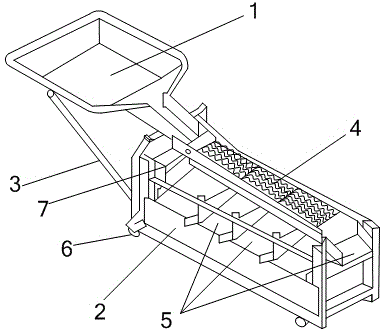

[0013] Such as figure 1 The plastic particle vibration screening device shown includes a feed hopper 1, a grading screen 4, a support 2 and a vibrator 7, the grading sieve 4 is supported on the support 2, the bottom of the grading sieve 4 is set in a stepped shape, and the surface is corrugated The grading sieve 4 is set as a multi-stage sieve hole with different apertures, the sieve hole diameter of the grading sieve 4 gradually increases from the entrance to the exit, a chute 5 is arranged below each stage of the sieve hole, and the vibrator 7 is fixed below the grading sieve 4, The feeding hopper 1 is arranged at the highest point of the support 2 and is provided with a channel communicating with the grading screen 4 , and a supporting horizontal frame 3 is arranged under the feeding hopper 1 .

[0014] When this program i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com