Steel wire rope transmission mechanical hand

A technology of manipulators and steel wire ropes, applied in the field of manipulators, can solve the problems of increasing the overall weight, volume, cost and internal consumption, reducing the ability and efficiency of manipulators to do work externally, and difficult to grab heavy objects, so as to achieve reasonable design and prevent chaos. effect of rope and load reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific technical solutions of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention, without limiting their rights.

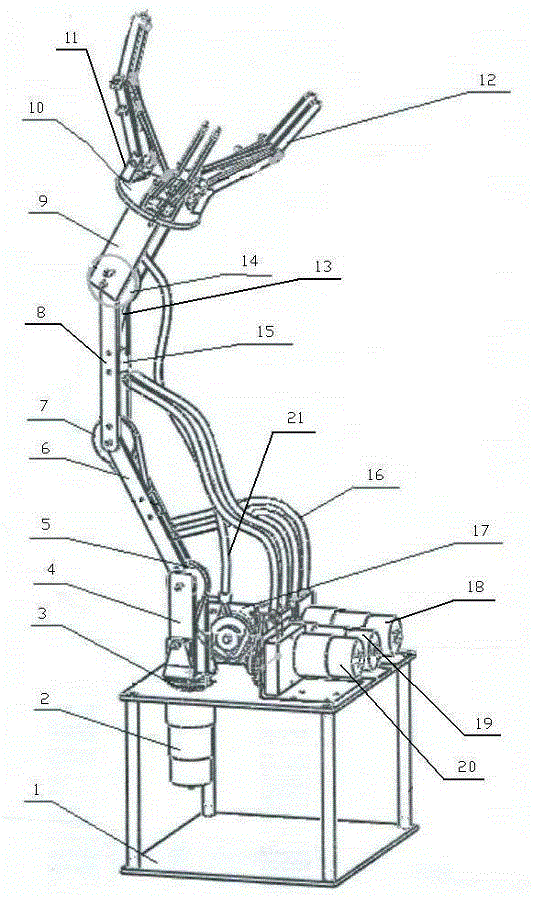

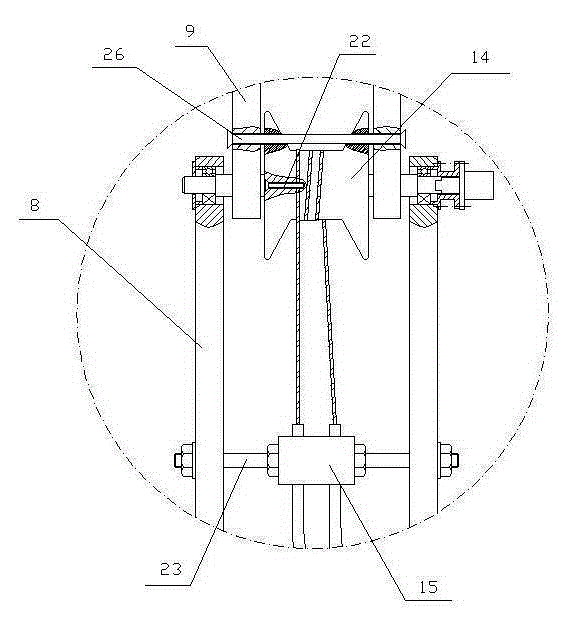

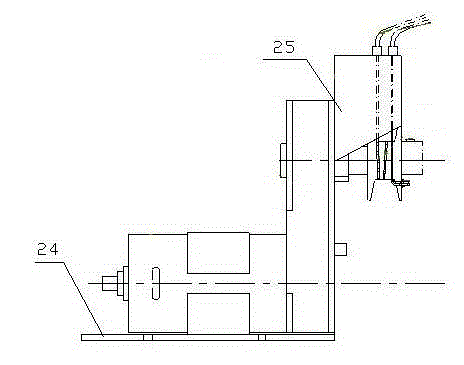

[0016] refer to Figure 1-3 , a manipulator driven by a wire rope, including a base frame 1 and a gripper located above the base frame 1, the gripper is connected to the base frame 1 through sequentially hinged wrist arms 9, small arms 8, large arms 6 and rotating arms 4 , the bottom frame 1 is provided with a rotary drive motor 2 connected with the rotating arm 4; The joint claw fingers are hinged, and the lower joint claw fingers are hinged with the finger base 11 located on the chassis 10; the wrist arm wheel 14 fixed with the wrist arm 9 is installed on the hinge shaft between the wrist arm 9 and the forearm 8. The small arm wheel 7 fixed with the small arm 8 is installed on the hinge shaft between the small arm 8 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com