Full-automatic chain saw sharpener and shape saw sharpening method using same

A chain grinding machine, fully automatic technology, applied in the field of tool grinding, can solve the problems of under-grinding, over-grinding of blades, etc., reduce the probability of over-grinding or under-grinding, improve precision, and the grinding process is accurate and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

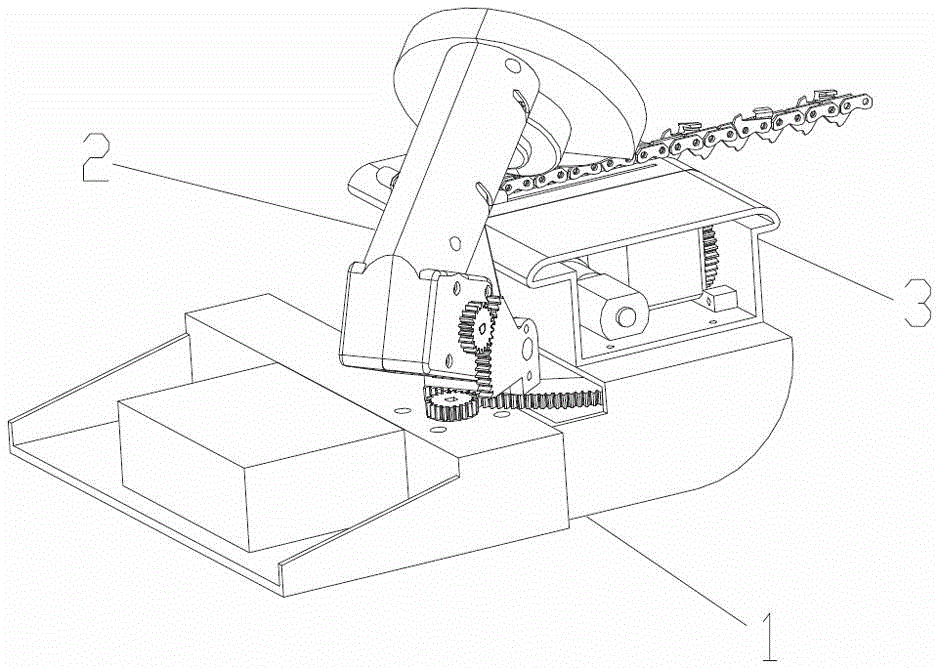

[0041] see figure 1 , the fully automatic saw chain sharpening machine of the present embodiment comprises:

[0042] The base 1 is provided with a saw chain grinding device 2 on one side of the base 1 and a chain feeding device 3 on the other side.

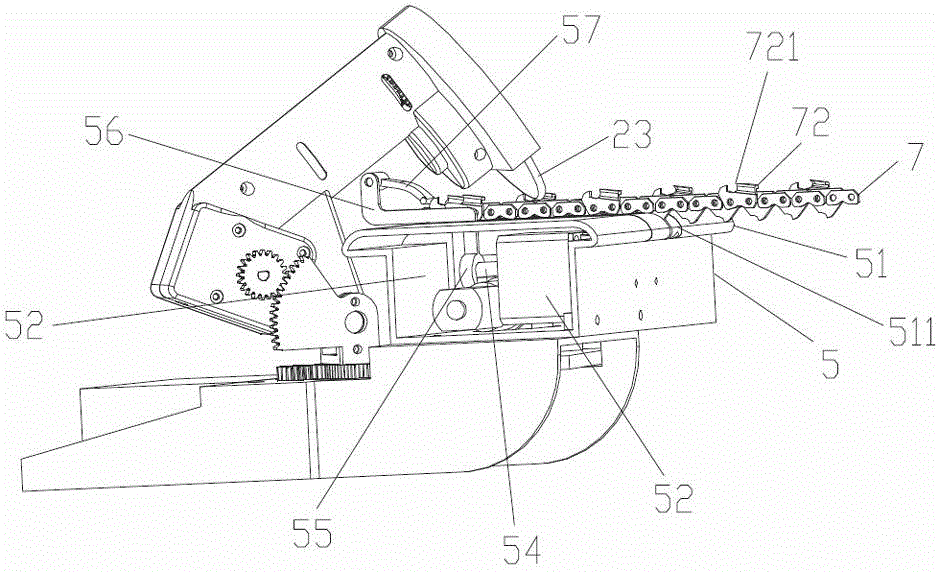

[0043] see figure 2, the saw chain grinding device further includes a saw chain grinding mechanism, a grinding head up / down mechanism and a grinding seat swing mechanism, wherein:

[0044] The saw chain grinding mechanism is used to grind the cutting edge of the blade;

[0045] The upward / downward mechanism of the grinding head is used to realize the upward or downward operation of the grinding head through the linkage of the grinding head with the saw chain grinding mechanism, and to control the adjustment of the grinding position of the saw chain grinding mechanism;

[0046] The grinding seat swing mechanism, through the grinding seat and the grinding head fixedly connected with it, jointly links the saw chain grinding mecha...

Embodiment 2

[0076] This embodiment provides another composition and structure of the chain delivery assembly, see Figure 8 , the chain feeding assembly includes a pull rod 57' for pulling the saw chain 7 forward, the pull rod 57' is provided with a hooked end 571 to pull the saw chain 7, the hooked end 571 can be integrally formed or fixed with the pull rod 57' Connected, the pull rod 57 ′ is pivotally connected to a support frame 56 ′, and the support frame 56 ′ passes through the second guide rail and is fixedly connected or integrally formed with the nut 55 . When the chain feeding assembly of this embodiment is working, the hooked end 571 is set in the groove between the limiting tooth 721 and the cutting tooth 722 of the saw chain 7, and then the saw chain 7 is pulled to move from front to back to the set position. Location. Other structures in this embodiment are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com