A machining method of double keyway with 180° distribution of shaft extension end of large motor

A large-scale motor and processing method technology, which is applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of inability to meet the requirements of high symmetry of double keyways, unfixed calibration datum, and low keyway processing accuracy. , to meet the requirements of high symmetry, improve processing quality, and achieve the effect of small error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to better understand the technical solutions of the present invention, detailed descriptions are given below through specific embodiments and in conjunction with the accompanying drawings.

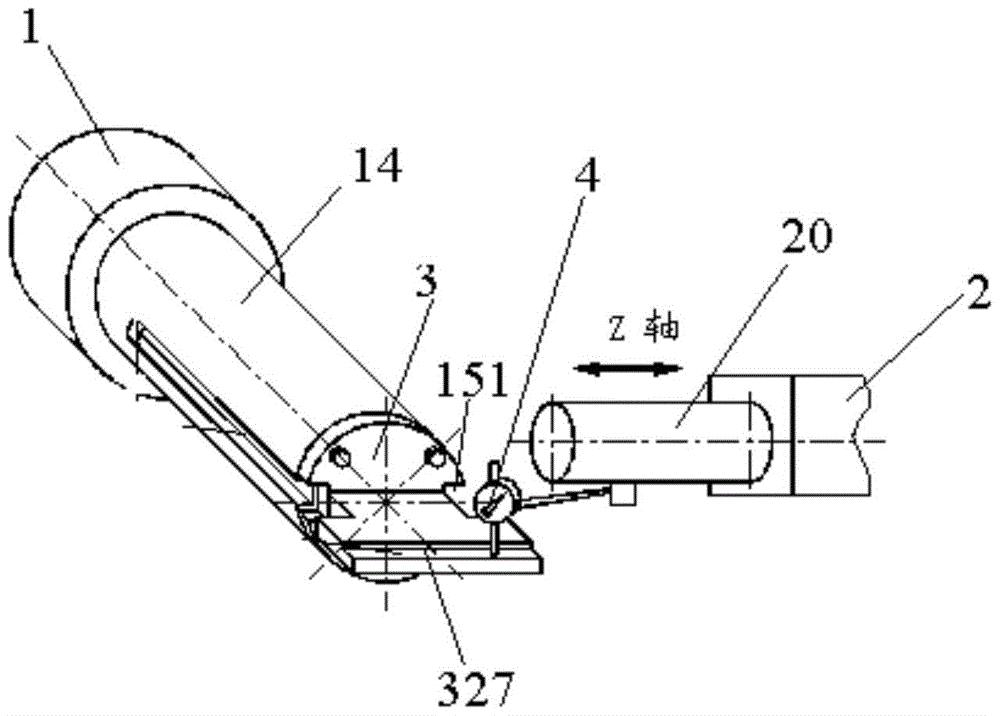

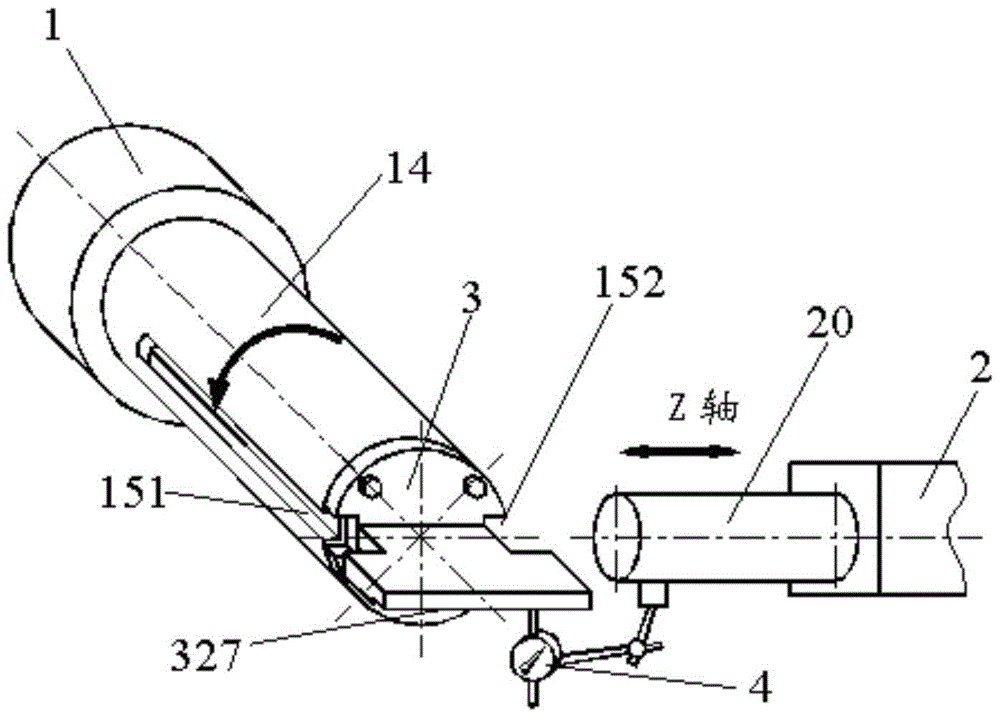

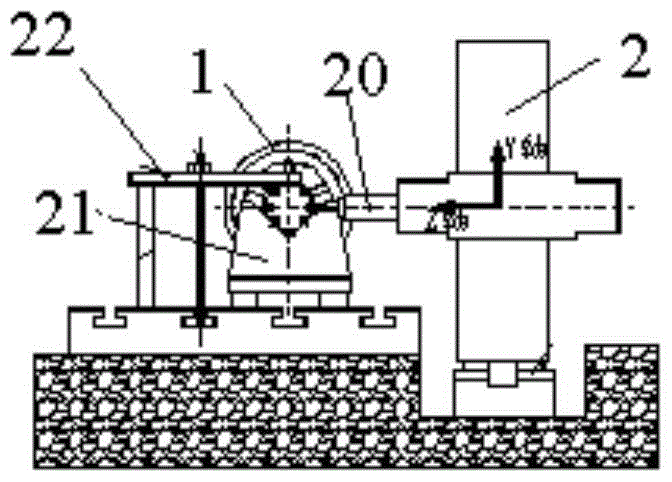

[0039] see figure 1 , figure 2 and image 3 , a method for processing double keyways with 180° distribution at the shaft extension end of a large motor of the present invention, comprising the following steps:

[0040] Step S1, install the rotor, including the rotor adjustment process and the rotor recalibration process:

[0041] Adjust the rotor process, put the rotor 1 of the large motor flat on the working platform of the boring and milling machine 2, support the rotor with the V-shaped iron 21, rotate the rotor 1 to a suitable position, and install the spindle 20 on the main shaft 20 of the boring and milling machine 2. Table 4, the measuring head of dial indicator 4 is placed on the outer circle of the bearing gear of rotor 1, and the upper busbar and side busbar o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com