Automatic stamping forming technology for K-shaped accessory plates and chain plates of chain and for combination of K-shaped accessory plates and chain plates of chain

A stamping forming and plate attaching technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of inaccurate bending size, low production efficiency, easy cracks in the bending parts, etc., to reduce processing equipment and Labor, improve product production efficiency, shorten the effect of product processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

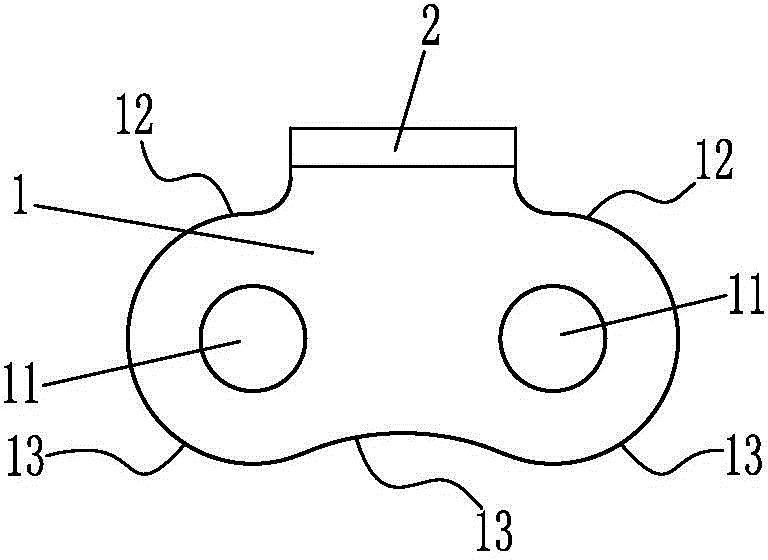

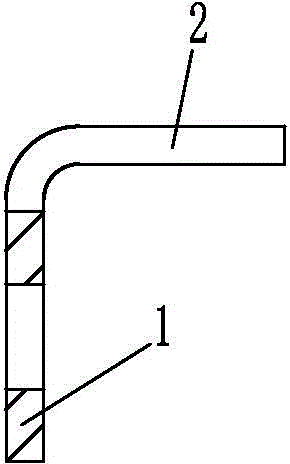

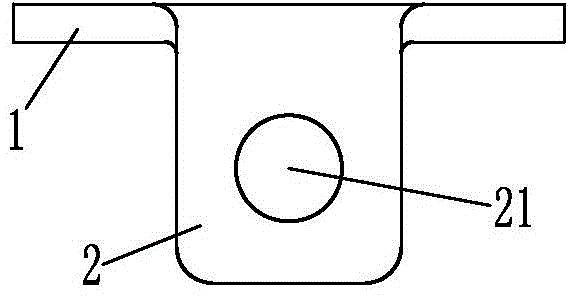

[0034] Such as Figure 4 A chain K-type attached plate and chain plate combined automatic stamping and forming process shown, adopts a multi-station continuous stamping die to carry out K-shaped attached plate and chain plate progressive stamping and forming process on the steel strip; the multi-station continuous stamping Mold layout: Insert two chain plates in the gap between two K-type attachment plates to form a combined layout of K-type attachment plates and chain plates. The two K-type attachment plates are arranged opposite to each other, and the The center connection line of the pin holes of the two attached plates is perpendicular to the progressive conveying direction of the steel belt, and the two chain plates are arranged opposite to each other, and the central connection line of the two chain plate holes of the chain plates is parallel to the progressive conveying direction of the steel belt; The multi-station continuous stamping die is arranged sequentially along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com